We and selected third parties use cookies or similar technologies for technical purposes and, with your consent, for other purposes. You can consent to the use of such technologies by using the “Accept” button, by closing this notice, by scrolling this page, by interacting with any link or button outside of this notice or by continuing to browse otherwise.

- CUTTING SOLUTIONS

- PRODUCTS

COMPLETE SYSTEMS

KMT waterjet OEM partner machines are powered by KMT pumps ranging from 6.200 bar to 3.800 bar, with installations available in over 100 countries.

PRO 6.200 bar Pumps – World’s Fastest Waterjet

The KMT Streamline PRO® 6.200 bar Waterjet Pumps will significantly increase production by cutting in less time and use up to 50% less abrasive to produce the Lowest Cost Per Part! The PRO pump is available in three horse-powers for a wide range of cutting applications: 125 and 60 PS

ABRALINE IV Abrasive Hopper

Precisely monitors abrasive feed usage during entire cutting process. Designed for large cutting machines which operate continuously and with multiple cutting heads. Capacity – 1.000 kg

STREAMLINE® SL-VI 4.100 bar Pumps

KMT Waterjet SL-VI Pumps have decades of proven performance and are considered the Industry Workhorse! The SL-VI Series of pumps are available in: 15, 30, 50 und 100 PS

ABRALINE V Abrasive Hopper

Precisely monitors abrasive feed usage during entire cutting process. Designed to sufficiently ensure the abrasive feed for average cutting needs. Capacity – 425 kg

KMT CLASSIC V-Drive 3.800 bar Energy Saving Pump

The STREAMLINE® CLASSIC with V-Drive combines the KMT proven intensifier concept with energy saving drive and control technology for energy savings and efficient waterjet cutting. Equipped with a speed-controlled motor drive, the CLASSIC V-Drive satisfies any criteria specifying an energy saving machinery.

FEEDLINE V Abrasive Feeder

Optimized abrasive consumption for customized applications. Controlled through a central CNC controller or a potentiometer, the FEEDLINE V supplies the cutting nozzle with the optimized flow of abrasive, saving material and costs.

ATS Abrasive Removal Systems

Never shut down production for tank clean outs again. The all new ATS 2200 or 4400 is the perfect way to improve your waterjet operations.

IDE® Diamond Cutting Heads

The KMT Waterjet IDE® (Integrated Diamond Eductor) One-piece Assembly Cutting Head is rated for pressures from 4.100 bar to 6.200 bar and is a waterjet nozzle breakthrough in simplicity & peak performance.

AUTOLINE® Cutting Heads

The self-aligning components of the KMT AUTOLINE® 4.100 bar and 6.200 bar cutting heads provide true, perfect alignment to extend the life of focusing tubes and mixing chambers.

AQUALINE® Water-only Cutting Heads

PROVEN PERFORMANCE AT EXTREME PRESSURES! Our AQUALINE® pure water pneumatic valves have gained an industry-wide reputation for being among the quickest and the most reliable pure water cutting heads under extreme working conditions.

KMT CUT Calculator App

Compare 6.200 bar vs. 4.100 bar cutting and see how much faster you get the job done and at a lower cost per part! The KMT Waterjet Cut Calculator 2.0 App incorporates 25 materials, offers a wider range of substrate thicknesses, horsepower, orifice size, and abrasive rates.

ARA 3.800 bar Pump

The Ara™ high-pressure pump meets all essential requirements for successful, economical and seamless operation of a waterjet cutting system. The highly reliable “SSEC” intensifier design is one of the key features of the AraTM pump.

- COMPLETE SYSTEMS

- ABRALINE IV Abrasive Hopper

- PRO 6.200 bar Pumps

- ABRALINE V Abrasive Hopper

- SL-VI 4.100 bar Pumps

- FEEDLINE V Meter

- Classic V-Drive 3.800 bar Pump

- ATS Abrasive Removal Systems

- ARA 3.800 bar Pump

- IDE Diamond Cutting Head

- AUTOLINE Cutting Head

- AQUALINE Water-only Cutting Head

- Cut Calculator App

- APPLICATIONS/INDUSTRIES

STREAMLINE® SL-VI 4.100 bar Waterjet Pumps

THE WATERJET INDUSTRY WORKHORSE

KMT Waterjet STREAMLINE® SL-VI 4.100 bar Pumps

Find out why THE RIGHT KMT PUMP MATTERS!

THE INDUSTRY WORKHORSE!

Since 1971, the STREAMLINE® SL-VI Series has been available with horsepower offerings of 11, 22, 37 and 74 kW at 4.100 bar. The SL-VI Series is a configurable water jet pump that can be custom-built based on a variety of options to meet your cutting solution requirements.

- Variety of materials: KMT water jet pumps are designed to cut a wide range of materials including metal, stone, composites, foam, and more.

- Horsepower and Pressure: Offering the broadest range of 4.100 bar UHP pumps from 11 kW – 74 kW .

- Precision Cutting: Integrated with over 180 global OEM partners to cut intricate and accurate cuts with minimal material wastage.

- Durability and Reliability: Engineered with robust components and built to withstand heavy-duty industrial applications for long-term reliability.

- Enhanced Safety: Waterjet cutting eliminates the generation of heat, dust, and hazardous fumes, providing a safer working environment for operators.

- Best overall value: For fabrication centers waterjet cutting 2-4 hours per day with thin materials, the Streamline series offers the best, proven overall value in the waterjet industry.

As the pioneers of waterjet cutting, the KMT Streamline Series pumps were purchased starting in 1971, because of proven reliability and ease of service.

From the basic model to the fully loaded, the result is a waterjet pump that delivers the highest efficiency and profit.

FEATURES

- Proven Waterjet Technology

- Configurable Design – from Basic to Fully Loaded

- Universal PLC – Global Network Support

- Power Factor Correction

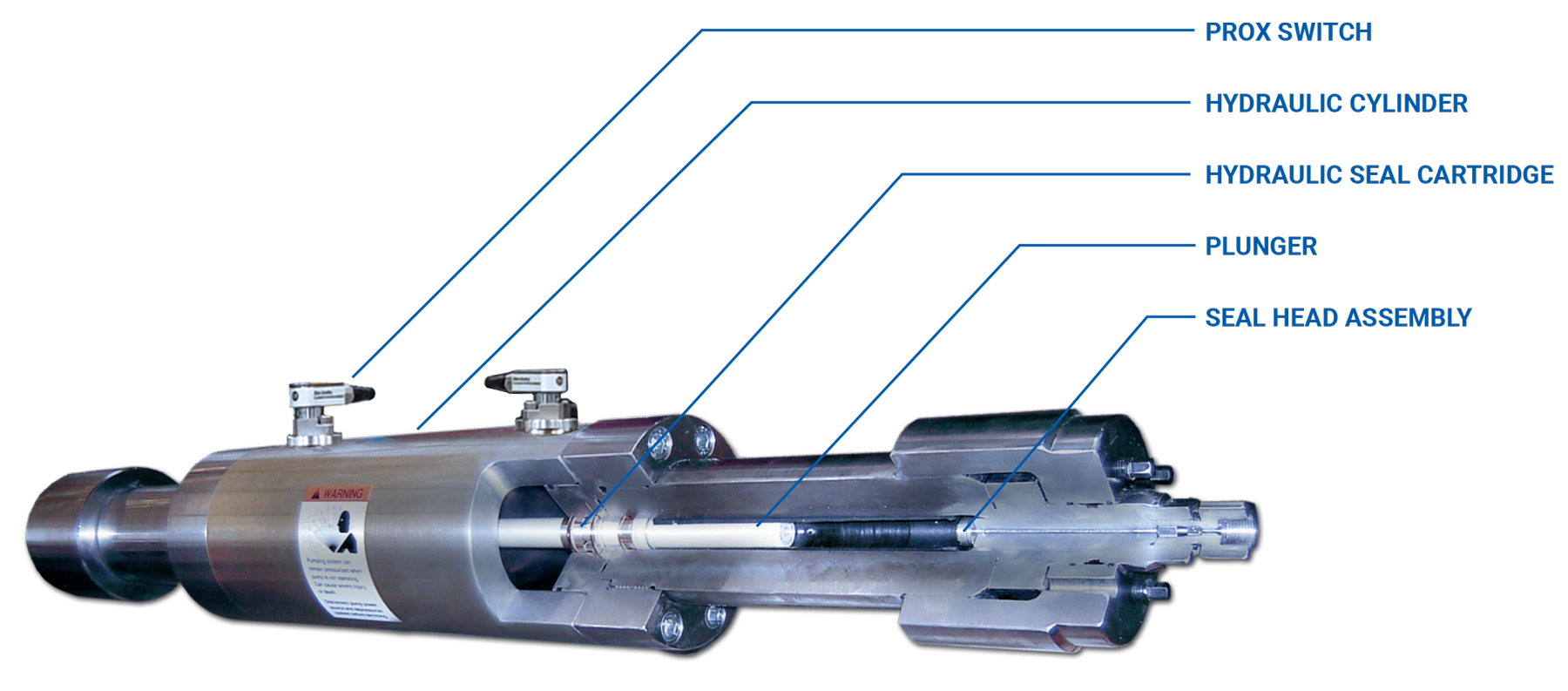

THE KMT STREAMLINE INTENSIFIER DIFFERENCE

The STREAMLINE® Intensifier employs long-stroke technology for ease of use, reliability maximum uptime. MILLIONS OF HOURS OF PROVEN PERFOMANCE!

INCREASED UPTIME

• QUICK CHANGE CERAMIC PLUNGER

• 20 MINUTE SEAL CHANGE*

• NO NEED TO REMOVE TOPWORKS FOR REPAIR**

*Based on experienced technician proper tools

**Lockout/tagout procedures must be followed

EASE OF MAINTENANCE

• ONE-PIECE CARTRIDGE HYDRAULIC SEAL

• HARD SEAL END CAP – Less parts: 1 seal vs. 2 seals, Small torque wrench

• MODULAR DESIGN – No tie rods

• NO SQUARING FIXTURE REQUIRED

REDUCED COMPONENT WEAR

• LONG STROKE – Longer life

• SMOOTH ELECTRONIC SHIFTING – Better edge quality

• ROBUST HIGH PRESSURE CYLINDER – Designed for waterjet applications

SL-VI SERIES PUMP SPECIFICATIONS

Below charts are a brief overview of pump specifications. Please see above catalog PDF on this page for detailed pump specifications.

- 11 kW

- 22 kW

- 37 kW

- 74 kW

| Description | Imperial | Metric |

|---|---|---|

| Motor Rating | 15hp | 11 kw |

| Pressure Range (Deadhead) | 60,000psi | 4.137 bar |

| Max. Flow Rate at Max. Pressure (60 hz) | 0.30 gpm | 1.14 L/min |

| Length | 56" | 1.400 mm |

| Width | 28" | 711 mm |

| Height | 33" | 838 mm |

| Weight | 1,800 lbs. | 816.46 kg |

| DESCRIPTION | IMPERIAL | METRIC |

|---|---|---|

| Motor Rating | 30 hp | 22 kw |

| Pressure Range (Deadhead) | 60,000 psi | 4.137 bar |

| Max. Flow Rate at Max. Pressure (60 hz) | 0.68 gpm | 2.6 L/min |

| Length | 66.5” | 1.689 mm |

| Width | 43.86” | 1.114 mm |

| Height | 58.15” | 1.477 mm |

| Weight | 2,900 lbs. | 1.315 kg |

| Please see PDF on this page for more specifications |

| DESCRIPTION | IMPERIAL | METRIC |

|---|---|---|

| Motor Rating | 50 hp | 37 kw |

| Pressure Range (Deadhead) | 60,000 psi | 4.137 bar |

| Max. Flow Rate at Max. Pressure (60 hz) | 1.0 gpm | 3.78 L/min |

| Length | 68" | 1.727 mm |

| Width | 46" | 1.168 mm |

| Height | 60" | 1.524 mm |

| Weight | 2,900 lbs. | 1.315 kg |

Please see PDF on this page for more specifications

| DESCRIPTION | IMPERIAL | METRIC |

|---|---|---|

| Motor Rating | 100 hp | 75 kw |

| Pressure Range (Deadhead) | 60,000 psi | 4.137 bar |

| Max. Flow Rate at Max. Pressure (60 hz) | 1.88 gpm | 7.12 L/min |

| Length | 84" | 2.134 mm |

| Width | 54" | 1.372 mm |

| Height | 60" | 1.524 mm |

| Weight | 4,200 lbs | 1.905 kg |

Please see PDF on this page for more specifications

KMT Waterjet cutting SOLUTIONS

PROVEN PERFORMANCE

The KMT SL-VI is the most recognized waterjet pump in the World.

Companies in a variety of industries have been using KMT Waterjet cutting products with great effectiveness for more than 53 years.

BROAD RANGE OF APPLICATIONS

• Precision cutting without waste eliminates second operation finishing

• Ability to cut nearly all types of materials thicknesses – from thin foils to 305 mm

• Waterjet cutting combines with other processing methods: laser, saws, plasma cutting punching

MOST FLEXIBLE CUTTING TOOL

Thanks to its flexibility and reliability, No Heat Affected Zone, no secondary finishing, waterjet technology is suitable for both large nesting productions as well as small series and complex specialized applications.

SL-VI COMPLETE CUTTING SYSTEMS

The KMT Waterjet global OEM network offers the largest variety of entry level, standard waterjet tables, large format machines, 5 axis motion control, and robotic integration in the waterjet industry including testing, designing, and manufacturing solutions.

Shape Process Automotion Robotic Waterjet Trimming---POWERED BY KMT PUMPS

This video shows Shape Process Automation waterjet trimming at six-axis, materials for the automotive industry.

Welcome to KMT Waterjet. To continue, please select a language from the options below.

HELP CENTER

Contact form

KMT Waterjet has global offices to assist you in your region. Contact us using the following form, and the message will be forwarded to the local office which can provide the best support.

Contact form

KMT Waterjet has global offices to assist you in your region. Contact us using the following form, and the message will be forwarded to the local office which can provide the best support.