We and selected third parties use cookies or similar technologies for technical purposes and, with your consent, for other purposes. You can consent to the use of such technologies by using the “Accept” button, by closing this notice, by scrolling this page, by interacting with any link or button outside of this notice or by continuing to browse otherwise.

- CUTTING SOLUTIONS

- PRODUCTS

COMPLETE SYSTEMS

KMT waterjet OEM partner machines are powered by KMT pumps ranging from 90,000 psi to 55,000 psi, with installations available in over 100 countries.

PRO 90,000 psi Pumps – World’s Fastest Waterjet

The KMT Streamline PRO® 90,000 psi Waterjet Pumps will significantly increase production by cutting in less time and use up to 50% less abrasive to produce the Lowest Cost Per Part! The PRO pump is available in three horse-powers for a wide range of cutting applications: 125, 60 and 50 HP

ADS Abrasive Hoppers

KMT Waterjet Systems ADS Series Abrasive Hoppers for Waterjet Machines are easily re-filled during the cutting process—no need to stop cutting! These hoppers are available in 2 sizes: 500 & 2,000 lb.

STREAMLINE® SL-VI 60,000 psi Pumps

KMT Waterjet SL-VI Pumps have decades of proven performance and are considered the Industry Workhorse! The SL-VI Series of pumps are available in: 15, 30, 50, 100 and 200 HP

500V Abrasive Hopper

Our 500 V Hopper precisely monitors the availability of sufficient abrasive closely during the entire cutting process and pneumatically transfers it to the onboard metering device.

KMT CLASSIC 60,000 psi Pump

The New STREAMLINE® CLASSIC Series employs long-stroke technology designed for ease of use, reliability and maximum uptime…Classic KMT with modern technology!

FEEDLINE V Abrasive Feeder

Optimized abrasive consumption for customized applications. Controlled through a central CNC controller or a potentiometer, the FEEDLINE V supplies the cutting nozzle with the optimized flow of abrasive, saving material and costs.

ARA™ 55,000 PSI PUMP

The Ara™ high-pressure pump meets all essential requirements for successful and seamless operation of a waterjet cutting system. The highly reliable intensifier design is one of the key features of the Ara™ pump and is one of the most successful and reliable KMT intensifier designs, called “HSEC”.

FEEDLINE PRECISION Abrasive Meter

The Feedline Precision Abrasive Metering System is an economical and reliable option for accurate delivery of abrasive to the cutting nozzle.

TRILINE® 55,000 psi Direct Drive Pump

The TRILINE® pump has an excellent cost of ownership value and can be used as a stand-alone unit for everyday cutting needs.

ATS Abrasive Removal Systems

Never shut down production for tank clean outs again. The all new ATS 2200 or 4400 is the perfect way to improve your waterjet operations.

IDE® Diamond Cutting Heads

The KMT Waterjet IDE® (Integrated Diamond Eductor) One-piece Assembly Cutting Head is rated for pressures up to 60,000 psi and 90,000 psi and is a waterjet nozzle breakthrough in simplicity & peak performance.

AUTOLINE® Cutting Heads

The self-aligning components of the KMT AUTOLINE® 60,000 psi and PRO 90,000 psi cutting heads provide true, perfect alignment to extend the life of focusing tubes and mixing chambers.

AQUALINE® Water-only Cutting Heads

PROVEN PERFORMANCE AT EXTREME PRESSURES! Our AQUALINE® pure water pneumatic valves have gained an industry-wide reputation for being among the quickest and the most reliable pure water cutting heads under extreme working conditions.

KMT CUT Calculator App

Compare 90,000 psi vs. 60,000 psi cutting and see how much faster you get the job done and at a lower cost per part! The KMT Waterjet Cut Calculator 2.0 App incorporates 25 materials, offers a wider range of substrate thicknesses, horsepower, orifice size, and abrasive rates.

NEO 60,000 psi Pump

The KMT Waterjet NEO Pump incorporates over 50 years of experience offering unparalleled waterjet cutting technological achievements.

- COMPLETE SYSTEMS

- ADS Abrasive Hoppers

- PRO 90,000 psi Pumps

- 500 V Abrasive Hopper

- SL-VI 60,000 psi Pumps

- FEEDLINE V Meter

- CLASSIC 60,000 psi Pump

- FEEDLINE PRECISION Meter

- NEO 60,000 psi Pump

- ATS Abrasive Removal Systems

- TRILINE 55,000 psi Pump

- IDE Diamond Cutting Head

- AUTOLINE Cutting Head

- AQUALINE Water-only Cutting Head

- Cut Calculator App

- APPLICATIONS/INDUSTRIES

HELP CENTER

Contact form

KMT Waterjet has global offices to assist you in your region. Contact us using the following form, and the message will be forwarded to the local office which can provide the best support.

The Advantages of Waterjet Cutting HVAC Insulation

Waterjet cutting in the HVAC industry has become an indispensable technology for job shop fabricators, offering precise and efficient solutions for a range of manufacturing processes.

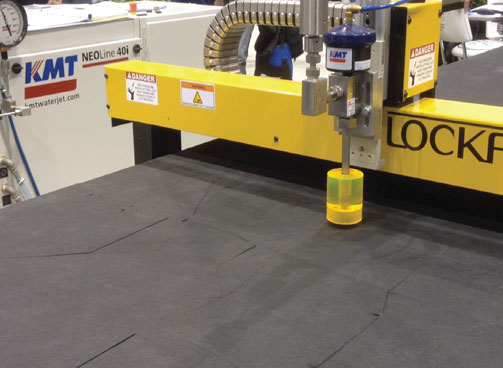

HVAC Insulation Cutting with KMT Waterjet

Waterjet cutting in the HVAC industry has become an indispensable technology for job shop fabricators, offering precise and efficient solutions for a range of manufacturing processes. Its versatility and ability to cut various materials make it a preferred choice for shaping components essential to HVAC systems.

Eliminate the duct liner bottleneck and reduce to slow, costly, and inexact manual process associated with cutting by hand.

Waterjet cut fiberglass, foam, rubber, gaskets, and more. Waterjet can cut up to 2,000 inches per minute.

Traditional techniques used for cutting HVAC duct work liners may compromise insulation strength and cause delamination.

Water jet cutting has no (HAZ) heat-affected zones with zero rough edges/burrs, eliminating the need for secondary finishing.

Waterjet cuts precise shapes, square to rounds or elbow cuts minimal waste, protecting material investment.

The cost is 1/10 the price of purchasing the fitted materials, meaning a quick Return on Investment ROI.

The speed of water jet technology is well suited to high production requirements for HVAC roll-forming machining.

ZERO-SCRAPE factor waterjet cutting compared to cutting with laser or plasma. ZERO waste from part to part.

The materials can be sheet-fed or coil-fed onto the waterjet table for cutting.

Advantages of Cutting HVAC with Waterjet:

- NO Heat Affected Zone (HAZ) or deformation to insulation material

- Safe for the Environment; no toxic fumes or dust and garnet is disposable

- Thick or thin, waterjet cutting is the most flexible cutting process for aluminum to foam

- Can pierce material directly without the need for a pre-drilled starter hole

- No tool or blade sharpening

- High or low surface pressure flexibility for sensitive or thick materials

- Waterjet cuts a variety of foams:

- Polyurethane foam

- Extruded polystyrene (XPS) foam

- Expanded polystyrene (EPS) foam

- Acoustic foam (e.g., open-cell or closed-cell acoustic foam)

- Neoprene foam

- Ethylene-vinyl acetate (EVA) foam

Since waterjet machining is a cold-cutting process, waterjet cutting is the preferred method for HVAC industry cutting based on minimal waste, precision accuracy, versatility, and efficiency.

♦ Unlike traditional techniques prone to manual errors and material compromise, waterjet cutting eliminates bottlenecks, ensuring precise cuts without heat-affected zones or rough edges ♦

Waterjet cuts fiberglass, foam, rubber, gaskets, and more. Its high-speed capabilities and minimal setup time make it ideal for meeting the demands of high-production requirements in HVAC manufacturing.

KMT Waterjet Custom HVAC Machines, Made in the USA

Welcome to KMT Waterjet. To continue, please select a language from the options below.

HELP CENTER

Contact form

KMT Waterjet has global offices to assist you in your region. Contact us using the following form, and the message will be forwarded to the local office which can provide the best support.