We and selected third parties use cookies or similar technologies for technical purposes and, with your consent, for other purposes. You can consent to the use of such technologies by using the “Accept” button, by closing this notice, by scrolling this page, by interacting with any link or button outside of this notice or by continuing to browse otherwise.

- CUTTING SOLUTIONS

- PRODUCTS

COMPLETE SYSTEMS

KMT waterjet OEM partner machines are powered by KMT pumps ranging from 6.200 bar to 3.800 bar, with installations available in over 100 countries.

PRO 6.200 bar Pumps – World’s Fastest Waterjet

The KMT Streamline PRO® 6.200 bar Waterjet Pumps will significantly increase production by cutting in less time and use up to 50% less abrasive to produce the Lowest Cost Per Part! The PRO pump is available in three horse-powers for a wide range of cutting applications: 125 and 60 PS

ABRALINE IV Abrasive Hopper

Precisely monitors abrasive feed usage during entire cutting process. Designed for large cutting machines which operate continuously and with multiple cutting heads. Capacity – 1.000 kg

STREAMLINE® SL-VI 4.100 bar Pumps

KMT Waterjet SL-VI Pumps have decades of proven performance and are considered the Industry Workhorse! The SL-VI Series of pumps are available in: 15, 30, 50 und 100 PS

ABRALINE V Abrasive Hopper

Precisely monitors abrasive feed usage during entire cutting process. Designed to sufficiently ensure the abrasive feed for average cutting needs. Capacity – 425 kg

KMT CLASSIC V-Drive 3.800 bar Energy Saving Pump

The STREAMLINE® CLASSIC with V-Drive combines the KMT proven intensifier concept with energy saving drive and control technology for energy savings and efficient waterjet cutting. Equipped with a speed-controlled motor drive, the CLASSIC V-Drive satisfies any criteria specifying an energy saving machinery.

FEEDLINE V Abrasive Feeder

Optimized abrasive consumption for customized applications. Controlled through a central CNC controller or a potentiometer, the FEEDLINE V supplies the cutting nozzle with the optimized flow of abrasive, saving material and costs.

ATS Abrasive Removal Systems

Never shut down production for tank clean outs again. The all new ATS 2200 or 4400 is the perfect way to improve your waterjet operations.

IDE® Diamond Cutting Heads

The KMT Waterjet IDE® (Integrated Diamond Eductor) One-piece Assembly Cutting Head is rated for pressures from 4.100 bar to 6.200 bar and is a waterjet nozzle breakthrough in simplicity & peak performance.

AUTOLINE® Cutting Heads

The self-aligning components of the KMT AUTOLINE® 4.100 bar and 6.200 bar cutting heads provide true, perfect alignment to extend the life of focusing tubes and mixing chambers.

AQUALINE® Water-only Cutting Heads

PROVEN PERFORMANCE AT EXTREME PRESSURES! Our AQUALINE® pure water pneumatic valves have gained an industry-wide reputation for being among the quickest and the most reliable pure water cutting heads under extreme working conditions.

KMT CUT Calculator App

Compare 6.200 bar vs. 4.100 bar cutting and see how much faster you get the job done and at a lower cost per part! The KMT Waterjet Cut Calculator 2.0 App incorporates 25 materials, offers a wider range of substrate thicknesses, horsepower, orifice size, and abrasive rates.

ARA 3.800 bar Pump

The Ara™ high-pressure pump meets all essential requirements for successful, economical and seamless operation of a waterjet cutting system. The highly reliable “SSEC” intensifier design is one of the key features of the AraTM pump.

- COMPLETE SYSTEMS

- ABRALINE IV Abrasive Hopper

- PRO 6.200 bar Pumps

- ABRALINE V Abrasive Hopper

- SL-VI 4.100 bar Pumps

- FEEDLINE V Meter

- Classic V-Drive 3.800 bar Pump

- ATS Abrasive Removal Systems

- ARA 3.800 bar Pump

- IDE Diamond Cutting Head

- AUTOLINE Cutting Head

- AQUALINE Water-only Cutting Head

- Cut Calculator App

- APPLICATIONS/INDUSTRIES

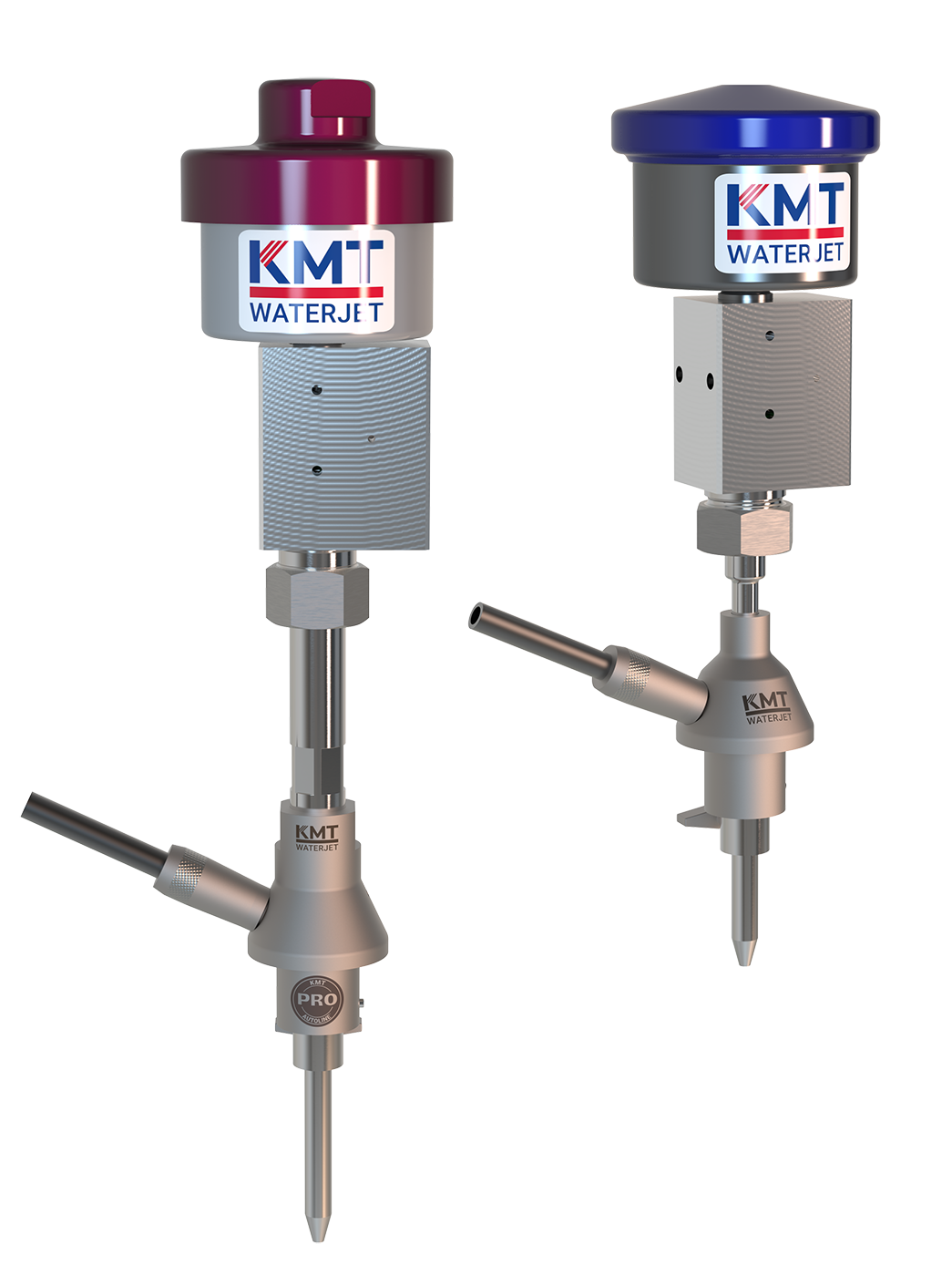

KMT Waterjet AUTOLINE® Abrasive Cutting Head

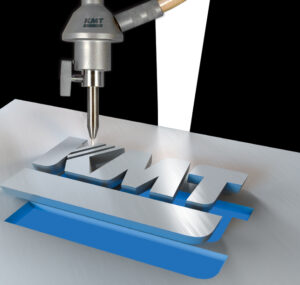

Best Applications for abrasive waterjet cutting

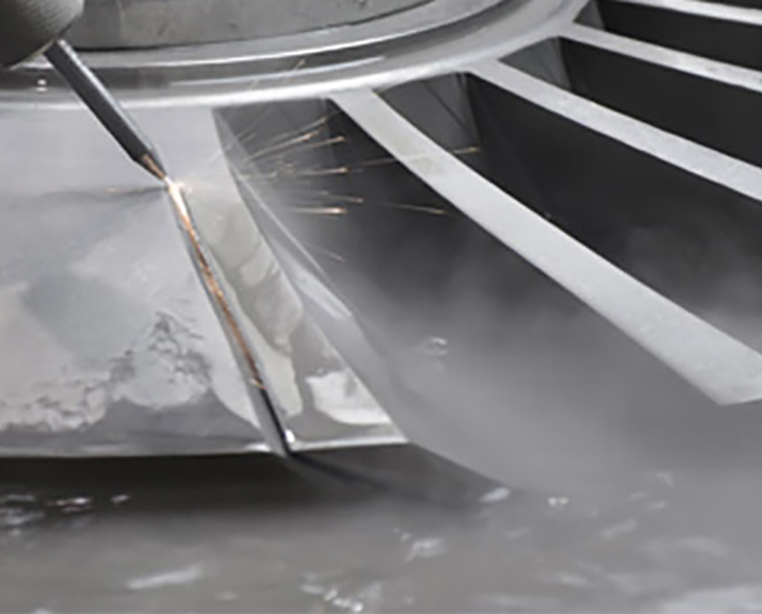

METAL | STONE | GLASS | COMPOSITES

KMT Waterjet AUTOLINE® Cutting Heads

ABRASIVE WATERJET HIGH SPEED, SELF-ALIGNING CUTTING NOZZLE

Focusing tubes last longer and wear evenly in an aligned cutting head.

The Autoline abrasive waterjet self-aligning components of the KMT AUTOLINE® (4.100 bar) and AUTOLINE PRO (6.200 bar) cutting heads provide true, perfect alignment to extend the life of focusing tubes and mixing chambers.

Proven to be the Best

Independent tests have shown that the KMT AUTOLINE® design is the ultimate in efficiency and has the lowest operating cost. Tests performed by the University of Missouri-Science Technology showed that the AUTOLINE® design achieved the best overall cutting performance for speed and efficiency

Everyone claims alignment, however, only the precision finish of the orifices in the AUTOLINE® series enable true precision alignment—even at pressures up to 6.200 bar!

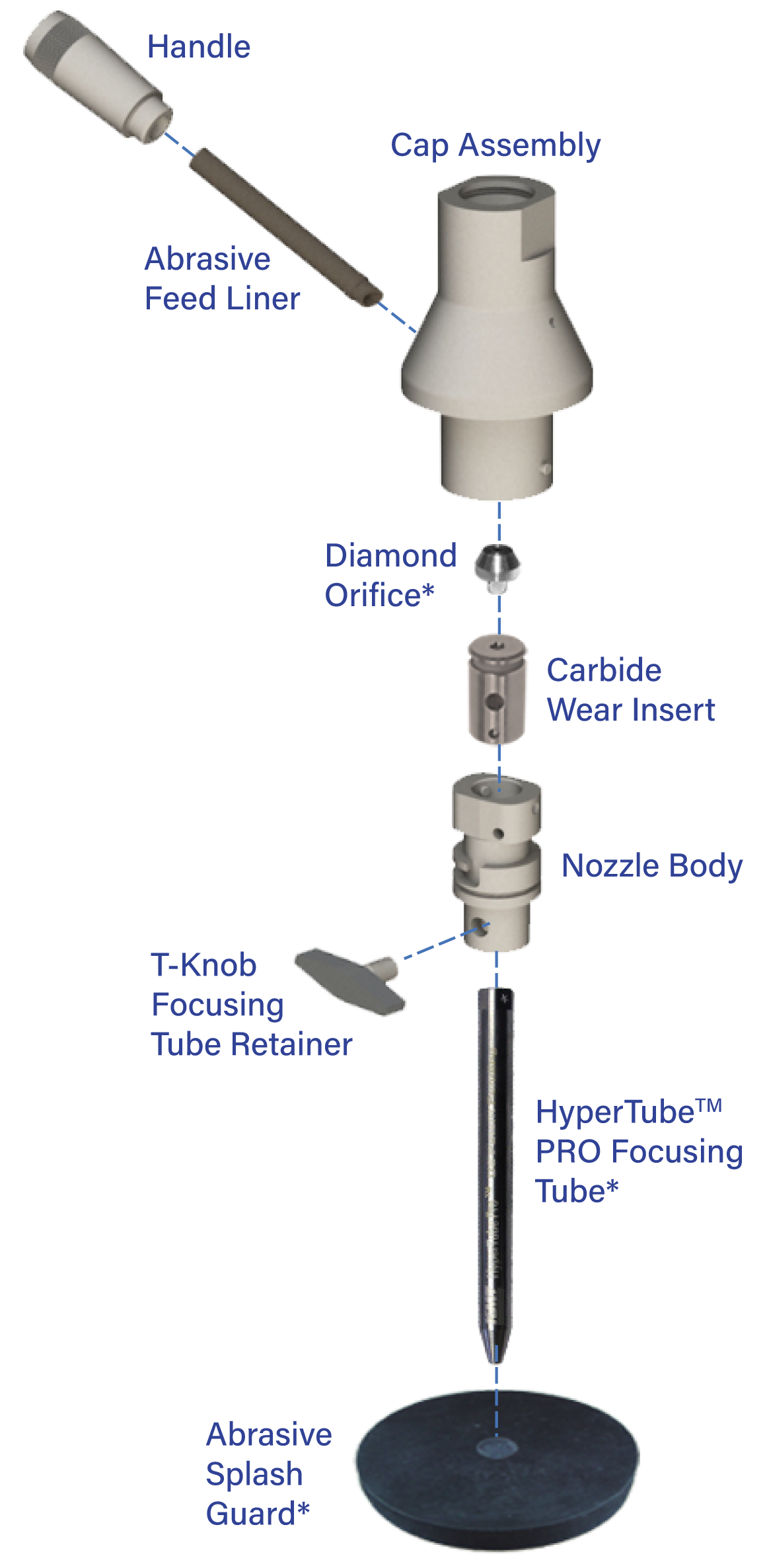

FEATURES SUMMARY

Wear Insert – Larger and relocated for visibility and easy access.

Same Interior Geometries – High performance cutting with very efficient abrasive usage.

Easy Orifice Change – No tools required.

Weep Hole Indicator – Shows when orifice needs to be tightened further, eliminating over-tightening to protect both the orifice and the nozzle tube.

Re-designed Knob – T-Knob designed for easy focusing tube tightening and dis-assembling.

Angled Abrasive Inlet – Inlet is mounted an angle which allows for a faster abrasive flow.

Easier Hose Attachment – Abrasive feed hose slips over inlet for easier visual attachment.

*Parts sold separately and in assembly kits

PRECISION

For waterjet cutting stainless steel, aluminum, titanium, or cutting composites, the KMT Waterjet Autoline cutting head ensures precision accuracy in every cut. Its advanced technology guarantees meticulous results with high consistency.

MULTI-HEAD CUTTING

The KMT Waterjet Autoline cutting head is optimized for CNC waterjet machines equipped with multiple cutting head assemblies. The perfect inset for the diamond jewel is perfectly aligned for efficient operation and synchronized cutting across all heads for enhanced productivity.

CUT THICK MATERIALS

For waterjet cutting thick titanium, aluminum or cutting mild steel, the KMT Waterjet Autoline is the preferred choice for a waterjet nozzle assembly, capable to change out the KMT diamond jewel in minutes when cutting thin materials including plastics, waterjet cutting composites and more.

KMT Waterjet Related Products

KMT Waterjet Systems | The Power to do More

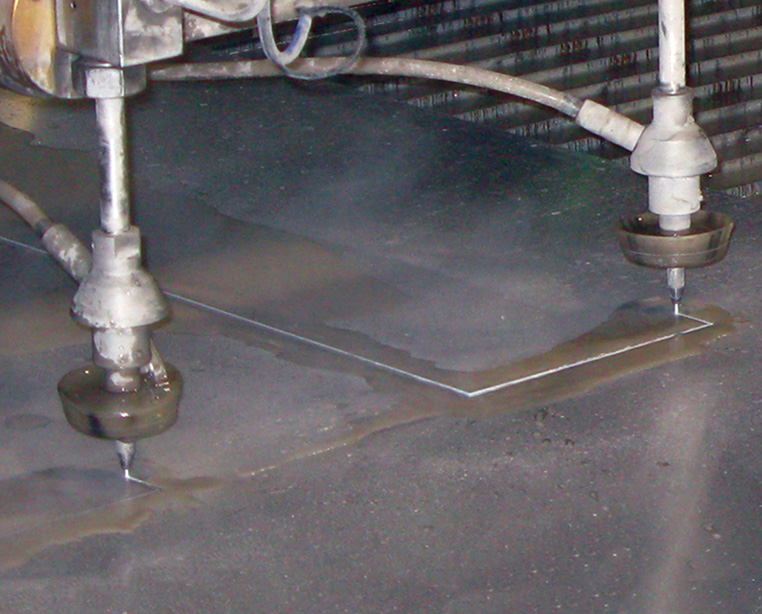

This KMT Waterjet video demonstrates how to cut aluminum faster at waterjet pressure 6.200 bar vs. 4.100 bar.

By increasing the waterjet pump pressure from 4.100 bar to 6.200 bar, the velocity of the water jet stream also significantly increases. The net result is, the higher the pressure, the faster the parts will cut. And by accelerating the water jet stream from 4.100 bar to 6.200 bar, there is also a reduction in the usage of abrasive costs.

This video shows a side-by-side comparison as to how much faster parts are cut, and how much less abrasive is used by cutting at 6.200 bar vs. 4.100 bar

KMT Service Engineers are regionally located to assist in cutting head installation to keep your system cutting with precision---PM Programs are available!

Welcome to KMT Waterjet. To continue, please select a language from the options below.

HELP CENTER

Contact form

KMT Waterjet has global offices to assist you in your region. Contact us using the following form, and the message will be forwarded to the local office which can provide the best support.

Contact form

KMT Waterjet has global offices to assist you in your region. Contact us using the following form, and the message will be forwarded to the local office which can provide the best support.