Machine - CUSTOM WATERJET SYSTEMS

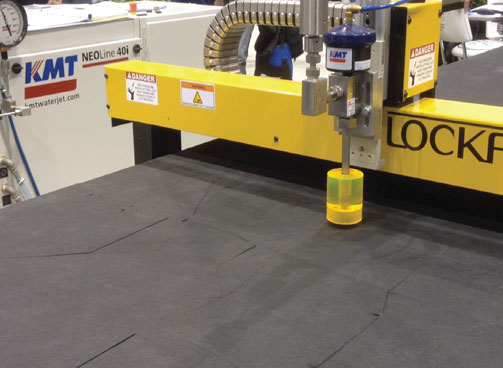

Custom waterjet systems, powered by KMT Waterjet, enable the precise cutting of components, used in the automotive, aerospace, and defense industries, ensuring high precision and minimal material waste.

CNC Custom Waterjet Systems, designed to specifications

Waterjet technology combined with customized machines serve diverse purposes, from cutting medical parts to lettuce in fields and desserts on cruise ships.

Waterjet technology combined with customized machines serve diverse purposes, from cutting medical parts to lettuce in fields and desserts on cruise ships.

Six-axis robotic waterjet cells precisely cut complex shapes in automotive materials like composites, glass, carpets, and headliners. The integration enhances manufacturing processes by significantly improving efficiency and accuracy in automotive part production.

Combination waterjet/plasma cutting machines, powered by KMT pumps and equipped with KMT abrasive cutting heads offer a versatile solution for various industrial cutting needs by integrating the strengths of both waterjet and plasma cutting technologies.

See the benefits of this combination cutting machine ⇒

In the food industry, custom waterjet systems ensure precise cutting of meats, fish, vegetables, and baked goods, enhancing efficiency and reducing product waste. These systems guarantee consistent portioning, vital for large-scale food production operations.

KMT Waterjet’s network of over 180 OEM integrators offers tailored solutions, leveraging top engineers and ultrahigh-pressure pumps for businesses.

Insulation Roll Cutting Tables

Insulation foam waterjet cutting systems have removed the slow, costly, and inexact procedures of manually cutting insulation with the power of water.

Waterjet can save 95% of the time it takes to cut insulation by hand while fabricating insulation fittings for about 10% of what it costs to buy them.

Field Waterjet Harvesting

Water jet machines can be designed with horizontal waterjet cutting jets, a method that increases yield and product shelf life.

Having an individual high-pressure water stream for every seed line allows to independently adjust cut height for uneven beds.

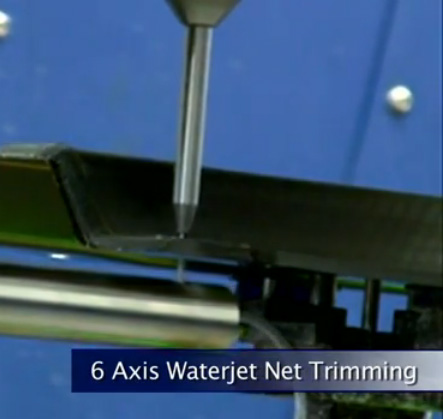

Waterjet Trimming

Waterjet cutting and trimming is a perfect solution when materials are susceptible to distortions from other cutting methods such as heat cutting.

Waterjet systems designed to true five-axis can provide the precision and dexterity needed to produce highly contoured parts of great complexity.

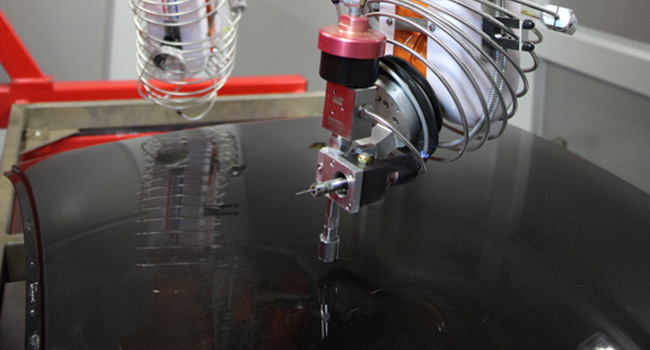

Micro-cutting

Micro-water jet custom designed machines enable access to a very precise technology to cut very hard materials in “close-to” 2D geometries.

The technology for micro waterjet cutting with fine abrasive was developed back in 2009 and is used in the medical and aerospace industries.

Custom designed Waterjet SYSTEMS, powered by KMT Waterjet

CUSTOM DESIGNED WATERJET CUTTING SYSTEMS FAQ'S

Q: How do custom waterjet systems improve manufacturing processes in the aerospace industry? A: Custom waterjet systems provide high precision and versatility, allowing for the cutting of various materials used in aerospace components, leading to improved efficiency and reduced waste.

WATERJET PRODUCE HARVESTER-RAMSAY HIGHLANDER

The Ramsay Highlander Waterjet Mechanical Harvester is designed to harvest Romaine, Green Leaf and a version for Iceberg and many other commodities. The patented Ramsay Highlander horizontal waterjet cutting method increases yield and product shelf life. Having an individual high-pressure water stream for every seed line allows to independently adjust cut height for uneven beds.