Machine CNC Cutting Waterjet systems with multi-axis cutting

For the best machine CNC cutting systems, choose the KMT Waterjet largest network of global OEM integrators that offers the most comprehensive range of waterjet cutting systems from 2-axis to 6-axis machines.

The advantages of machine CNC cutting waterjet tables using multi-axis

Multi-axis waterjet cutting is an advanced manufacturing process that utilizes high-pressure water, often mixed with an abrasive material, to cut a wide variety of materials. This technique is known for its precision, versatility, and ability to cut intricate shapes without generating heat-affected zones.

Here are some key features of Multi-Axis Waterjet Cutting (Multiple Axes of Movement):

2-axis: Basic waterjet cutting, where the cutting head moves in the X and Y directions.

3-axis: Adds the ability to control the height (Z-axis), allowing for depth cutting and three-dimensional shapes.

4-axis: Introduces an additional rotational axis (typically the A-axis), enabling the cutting head to tilt while moving along the X, Y, and Z axes.

5-axis: The most advanced, with the cutting head capable of moving along the X, Y, and Z axes while also tilting and rotating (B-axis), allowing for complex and angled cuts on three-dimensional surfaces.

Here are the advantages of Multi-Axis Waterjet Cutting:

Flexibility: Can cut virtually any material and handle a wide range of thicknesses.

Precision: High degree of accuracy and edge quality, reducing the need for secondary finishing processes.

Material

Savings: Narrow kerf width minimizes material waste.

Safety: Cold cutting process reduces risks associated with heat and fumes.

Cost-Effective: Reduces the need for multiple machining processes and tools.

Cost-Effective: Reduces the need for multiple machining processes and tools.

From cutting thick metals, stainless steel, or composites for the automotive or aerospace industries with high gantry tables, to mitering marble, granite and quartz for stone construction, specialized foam components and in the remodeling industry, the KMT OEM network has the solution you need for your application.

Our global KMT Waterjet sales team, with regional offices in the United State, Europe, and the Asia-Pacific region can provide you with same day support.

⇒ The KMT OEM network offers complete waterjet cutting systems engineering beyond imagination.

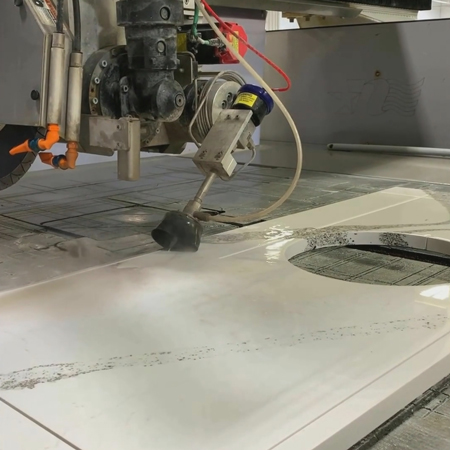

Machine CNC Cut Specialized Tables

Nearly every type of cut is possible, from using waterjet tables for rapid hole drilling to detailed cuts for automotive applications.

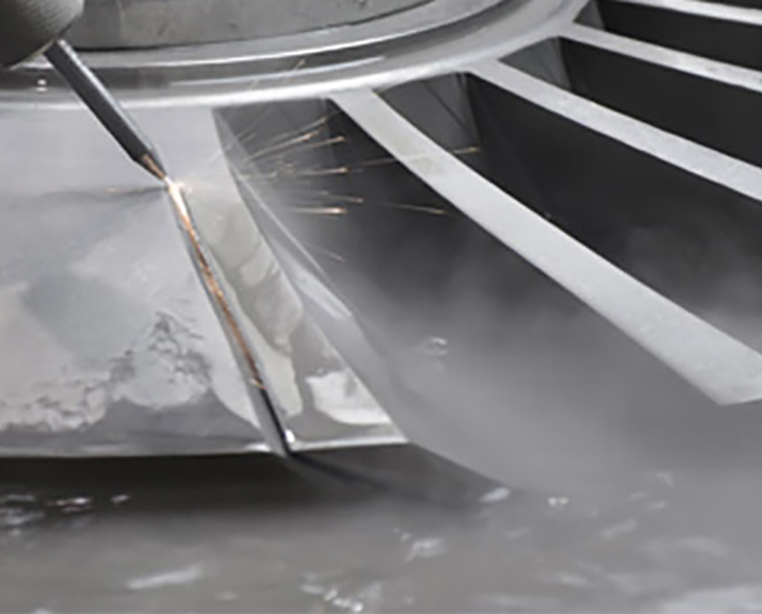

Bevel and Angle CNC machine cutting

Specialized bevel edge cutting in the building industry for marble kitchen sink cutouts with clean beveled counter top edges.

Large and Small CNC waterjet cutting jobs

Customized large scale waterjet systems easily respond to customer project demands in cutting over sized parts and components.

No HAZ (Heat Affected Zone) CNC waterjet

Waterjet machining is a cold cutting process, making it ideal for automotive, medical and aerospace applications where material like composites cannot be affected by heat.

MULTI-AXIS WATERJET CUTTING FAQ'S

Q: What is a multi-axis CNC waterjet cutting system? A: A multi-axis CNC waterjet cutting system is a machine that uses high-pressure water, often mixed with an abrasive, to cut materials. It operates with multiple axes (typically three to five) allowing for complex cuts in three dimensions.

Trimming automotive headliners with four robotic MULTI-AXIS heads

Shape Process Automation robotic slitting soft materials

Powered by KMT technology at 60,000psi, 100hp pump