FAQ'S - MULTI-AXIS CUTTING MACHINES

MACHINE SYSTEMS FOR MULTI-AXIS WATERJET CUTTING

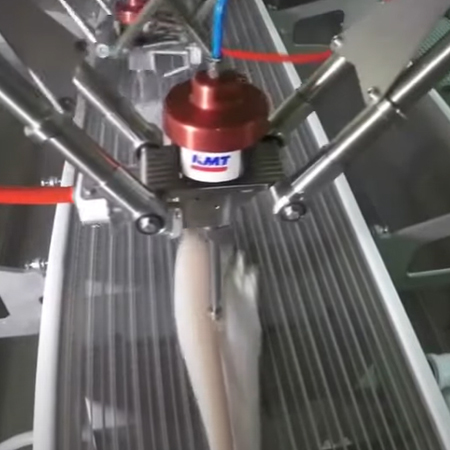

KMT Waterjet has over 180 OEM complete system integrators worldwide, enabling the creation of customized waterjet systems to meet specific requirements. These systems are commissioned in over 100 countries, ensuring that businesses have access to cutting-edge technology for their manufacturing needs.

Listed below are twenty FAQs relating to multiple axis (XYZ) CNC waterjet complete systems. To answer any of your questions, contact KMT Waterjet at sales@kmtwaterjet.com.

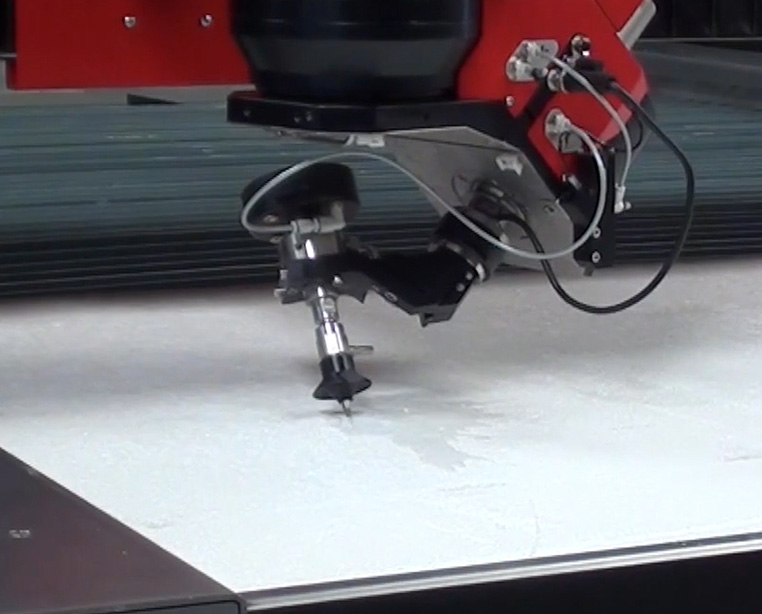

What is a multi-axis CNC waterjet cutting system? A multi-axis CNC waterjet cutting system is a machine that uses high-pressure water, often mixed with an abrasive, to cut materials. It operates with multiple axes (typically three to five) allowing for complex cuts in three dimensions.

How does a multi-axis waterjet system differ from a standard waterjet cutter? A standard waterjet cutter usually operates on two axes (XY) and is limited to flat, 2D cutting. A multi-axis system includes additional axes (Z for vertical movement, and potentially A and B for rotational movements), enabling it to cut complex 3D shapes and angles.

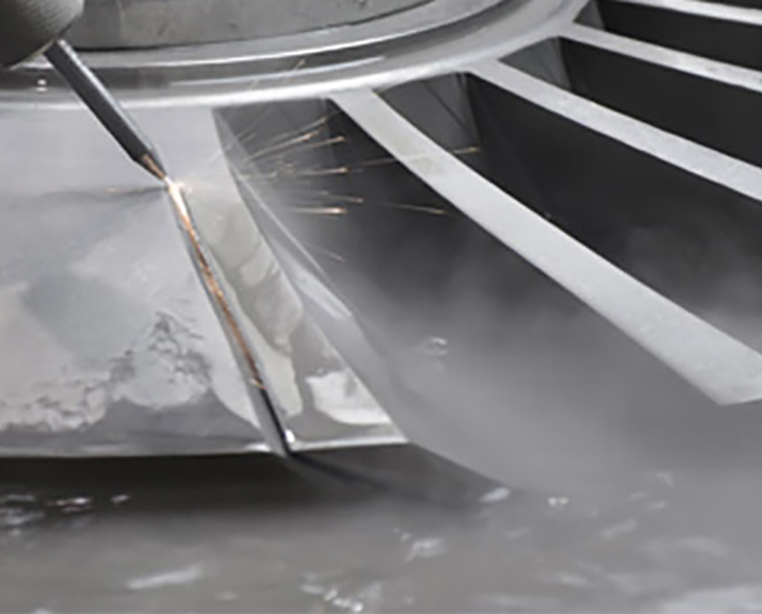

What materials can be cut using a multi-axis CNC waterjet system? These systems can cut a wide range of materials including metals (steel, aluminum, titanium), stone (marble, granite), glass, ceramics, composites, rubber, and plastics. Even the food industry uses multiple axis cutting, especially for seafood processing to cut out pinbones from fish.

These systems can cut a wide range of materials including metals (steel, aluminum, titanium), stone (marble, granite), glass, ceramics, composites, rubber, and plastics. Even the food industry uses multiple axis cutting, especially for seafood processing to cut out pinbones from fish.

What industries commonly use multi-axis CNC waterjet cutting systems? Industries such as aerospace, automotive, construction, metal fabrication, and art and design frequently use multi-axis CNC waterjet cutting systems for their versatility and precision. Stone fabrication shops use the combination waterjet/saw disc blades on a five-axis rotation for mitering kitchen countertops for a perfect fit.

How accurate are multi-axis CNC waterjet cutting systems? Multi-axis CNC waterjet cutting systems are highly accurate, typically achieving tolerances within ±0.001 inches (±0.025 mm), depending on the material and thickness being cut.

What are the advantages of using a multi-axis CNC waterjet system? Advantages include high precision, ability to cut complex shapes, versatility in material cutting, no heat-affected zones, and environmentally friendly operation with no hazardous fumes. Using KMT Waterjet pumps and cutting nozzles with 90,000 psi operating pressure, maximizes productivity, improves capacity, and reduces the cost per part, making it an efficient choice for manufacturers.

What is the role of abrasives in waterjet cutting? Abrasives, commonly referred to as garnet, are added to the high-pressure water stream to enhance the cutting power, especially for hard materials like metals and stone. The abrasive particles help erode the material efficiently.

What is the typical pressure range for a waterjet cutting system? The pressure range for waterjet cutting systems are between 55,000 and 90,000 psi (pounds per square inch). Using KMT Waterjet pumps and cutting nozzles at 90,000psi allows for faster and more efficient cutting, optimizing productivity, at a significantly operating cost. Cutting faster increases.

How does a multi-axis waterjet system ensure precision in cutting? Precision is ensured through advanced CNC controls, including the use of a 4th-axis taper control compensation to make sure the edges are smooth. The high-quality nozzles and diamond jewel orifices, precise abrasive flow control metering systems, and regular calibration and maintenance of the machine, all contribute to tight tolerances. Also, waterjet cutting at 90,000psi offers the thinnest water stream (.010 or .011) for minimal product waste for valuable and expensive parts.

Can multi-axis waterjet systems cut thick materials? Yes, multi-axis waterjet systems can cut through thick materials, up to 17inches of aluminum or titanium, depending on the material type and machine specifications.

What are the maintenance requirements for a multi-axis CNC waterjet cutting system? Maintenance includes regular inspection and replacement of nozzles and orifices, monitoring the high-pressure pump, cleaning the abrasive feed system, and keeping the CNC software up-to-date. The KMT Waterjet global field service engineers are available in 65 countries, speaking in twelve languages, to provide preventive maintenance programs to ensure maximum uptime of the KMT Waterjet pump.

How does waterjet cutting compare to laser cutting? Waterjet cutting does not generate heat, eliminating heat-affected zones and preserving material properties. It can cut a wider range of materials and thicker sections than laser cutting, which is limited by thermal effects and material reflectivity. KMT Waterjet systems offer cost-effective manufacturing due to their high efficiency and low operational costs.

What is the typical lifespan of a multi-axis CNC waterjet cutting machine With proper maintenance, a multi-axis CNC waterjet cutting machine can last many years, often exceeding 15-20 years, depending on usage and care. There are many KMT Waterjet pumps still in use today with over 25 years of running pump hours.

Are there any environmental concerns associated with waterjet cutting? Waterjet cutting is environmentally friendly as it does not produce hazardous fumes or waste. However, proper disposal of used water and abrasive materials is necessary to minimize environmental impact.

What is the cost range for a multi-axis CNC waterjet cutting system? The cost can vary widely depending on the machine’s capabilities, size, and features, typically ranging from $100,000 to over $500,000 for a robotic system with multiple cells. Investing in a KMT Waterjet system ensures long-term savings through enhanced productivity and lower cost per part. By cutting faster at 90,000psi, will reduce the use of the pump performance by 30%, compared to cutting at 60,000psi.

Can a multi-axis waterjet cutting system be used for prototyping? Yes, these systems are ideal for prototyping due to their versatility, precision, and ability to quickly switch between different materials and designs.

What software is typically used to control a multi-axis CNC waterjet system? With over 180 KMT Waterjet global OEM integrators, these manufacturers offer a variety of multi-axis CNC waterjet systems and use specialized CAD/CAM software designed for waterjet cutting, which allows for precise control and programming of complex cuts.

How fast can a multi-axis waterjet system cut? Cutting speed depends on material type, thickness, and desired precision. While it can vary, typical cutting speeds range from a few inches per minute to several feet per minute. Using KMT Waterjet pumps with 90,000 psi can significantly increase cutting speeds, enhancing productivity, while providing the lowest cost per finished part to maximize profitability and to get the jobs completed up to 100% faster than cutting at 60,000psi.

Can multi-axis waterjet cutting systems create bevel and miter cuts? Yes, with the additional axes (A and B), these systems can create bevel cuts and other complex geometries that are not possible with standard XY waterjet cutters. Mitering is very popular in the stone industry and KMT Waterjet OEMs specialize in combination waterjet/saw disc blade systems to choose from.

What safety precautions should be taken when operating a multi-axis CNC waterjet cutting system? Operators should wear protective gear, including safety glasses and hearing protection, follow proper training protocols, ensure regular maintenance, and keep the work area clean and free from obstructions. Safety interlocks and emergency stop mechanisms should always be functional and used when necessary.