We and selected third parties use cookies or similar technologies for technical purposes and, with your consent, for other purposes. You can consent to the use of such technologies by using the “Accept” button, by closing this notice, by scrolling this page, by interacting with any link or button outside of this notice or by continuing to browse otherwise.

- CUTTING SOLUTIONS

- PRODUCTS

COMPLETE SYSTEMS

KMT waterjet OEM partner machines are powered by KMT pumps ranging from 90,000 psi to 55,000 psi, with installations available in over 100 countries.

PRO 90,000 psi Pumps – World’s Fastest Waterjet

The KMT Streamline PRO® 90,000 psi Waterjet Pumps will significantly increase production by cutting in less time and use up to 50% less abrasive to produce the Lowest Cost Per Part! The PRO pump is available in three horse-powers for a wide range of cutting applications: 125, 60 and 50 HP

ADS Abrasive Hoppers

KMT Waterjet Systems ADS Series Abrasive Hoppers for Waterjet Machines are easily re-filled during the cutting process—no need to stop cutting! These hoppers are available in 2 sizes: 500 & 2,000 lb.

STREAMLINE® SL-VI 60,000 psi Pumps

KMT Waterjet SL-VI Pumps have decades of proven performance and are considered the Industry Workhorse! The SL-VI Series of pumps are available in: 15, 30, 50, 100 and 200 HP

500V Abrasive Hopper

Our 500 V Hopper precisely monitors the availability of sufficient abrasive closely during the entire cutting process and pneumatically transfers it to the onboard metering device.

KMT CLASSIC 60,000 psi Pump

The New STREAMLINE® CLASSIC Series employs long-stroke technology designed for ease of use, reliability and maximum uptime…Classic KMT with modern technology!

FEEDLINE V Abrasive Feeder

Optimized abrasive consumption for customized applications. Controlled through a central CNC controller or a potentiometer, the FEEDLINE V supplies the cutting nozzle with the optimized flow of abrasive, saving material and costs.

ARA™ 55,000 PSI PUMP

The Ara™ high-pressure pump meets all essential requirements for successful and seamless operation of a waterjet cutting system. The highly reliable intensifier design is one of the key features of the Ara™ pump and is one of the most successful and reliable KMT intensifier designs, called “HSEC”.

FEEDLINE PRECISION Abrasive Meter

The Feedline Precision Abrasive Metering System is an economical and reliable option for accurate delivery of abrasive to the cutting nozzle.

TRILINE® 55,000 psi Direct Drive Pump

The TRILINE® pump has an excellent cost of ownership value and can be used as a stand-alone unit for everyday cutting needs.

ATS Abrasive Removal Systems

Never shut down production for tank clean outs again. The all new ATS 2200 or 4400 is the perfect way to improve your waterjet operations.

IDE® Diamond Cutting Heads

The KMT Waterjet IDE® (Integrated Diamond Eductor) One-piece Assembly Cutting Head is rated for pressures up to 60,000 psi and 90,000 psi and is a waterjet nozzle breakthrough in simplicity & peak performance.

AUTOLINE® Cutting Heads

The self-aligning components of the KMT AUTOLINE® 60,000 psi and PRO 90,000 psi cutting heads provide true, perfect alignment to extend the life of focusing tubes and mixing chambers.

AQUALINE® Water-only Cutting Heads

PROVEN PERFORMANCE AT EXTREME PRESSURES! Our AQUALINE® pure water pneumatic valves have gained an industry-wide reputation for being among the quickest and the most reliable pure water cutting heads under extreme working conditions.

KMT CUT Calculator App

Compare 90,000 psi vs. 60,000 psi cutting and see how much faster you get the job done and at a lower cost per part! The KMT Waterjet Cut Calculator 2.0 App incorporates 25 materials, offers a wider range of substrate thicknesses, horsepower, orifice size, and abrasive rates.

NEO 60,000 psi Pump

The KMT Waterjet NEO Pump incorporates over 50 years of experience offering unparalleled waterjet cutting technological achievements.

- COMPLETE SYSTEMS

- ADS Abrasive Hoppers

- PRO 90,000 psi Pumps

- 500 V Abrasive Hopper

- SL-VI 60,000 psi Pumps

- FEEDLINE V Meter

- CLASSIC 60,000 psi Pump

- FEEDLINE PRECISION Meter

- NEO 60,000 psi Pump

- ATS Abrasive Removal Systems

- TRILINE 55,000 psi Pump

- IDE Diamond Cutting Head

- AUTOLINE Cutting Head

- AQUALINE Water-only Cutting Head

- Cut Calculator App

- APPLICATIONS/INDUSTRIES

HELP CENTER

Contact form

KMT Waterjet has global offices to assist you in your region. Contact us using the following form, and the message will be forwarded to the local office which can provide the best support.

WATERJET CUTTING MACHINES, POWERED BY KMT PUMPS

COMPLETE WATERJET SYSTEMS. A MACHINE FOR EVERY CUTTING NEED AROUND THE WORLD.

With over 180 global OEM integrators, the KMT original equipment manufacturer’s network of complete waterjet systems extends to over 100 countries around the world. This extensive network enables customers from various industries and geographic locations to access cutting-edge waterjet technology to grow their businesses.

Welcome to the KMT Waterjet OEM Group, offering the broadest range of complete waterjet solutions.

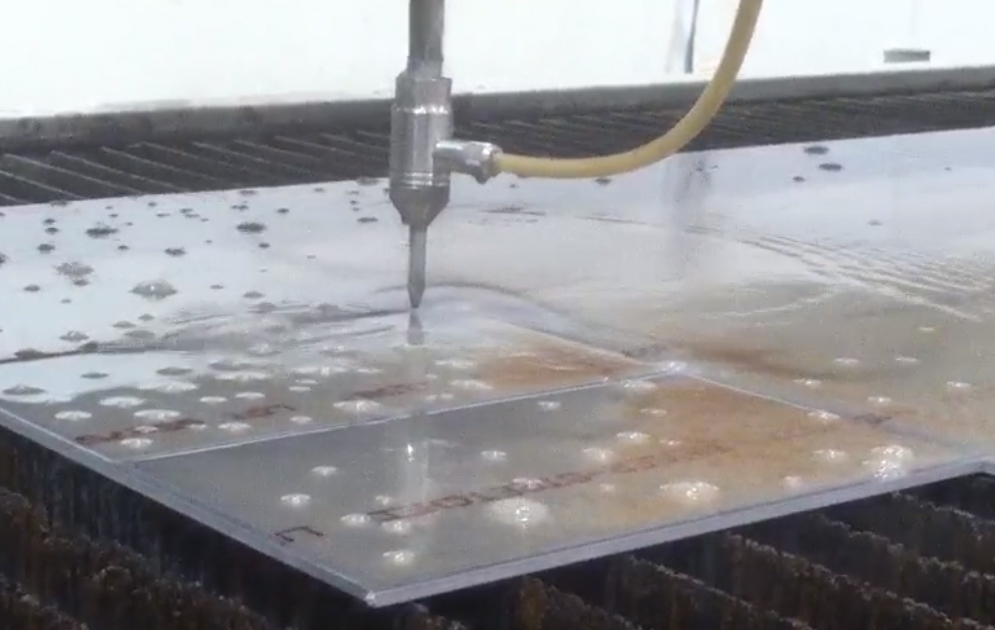

![]() X-Y WATERJET SYSTEMS

X-Y WATERJET SYSTEMS

Powered by KMT Waterjet pumps, X/Y waterjet cutting systems refer to a type of waterjet cutting technology where the cutting head moves along both the X-axis (horizontal) and the Y-axis (vertical) cut-through materials.

This two-axis movement allows for intricate shapes and precise cuts in a variety of materials, including metals, composites, glass, stone, ceramics, and food.

![]()

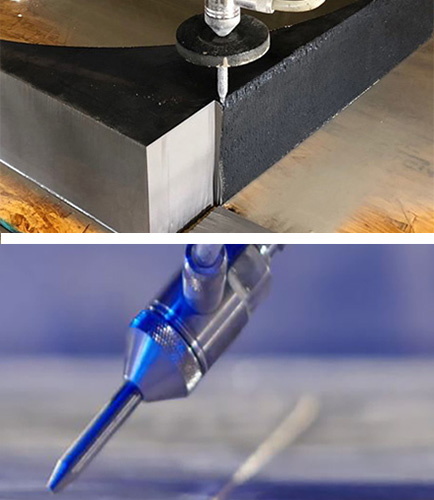

X-Y-Z (MULTI-AXIS) WATERJET TABLES

Three-axis cutting, often referred to as XYZ cutting, involves the movement of the water jet cutting head along three perpendicular axes: X, Y, and Z. The Z-axis represents depth or thickness adjustment. XYZ enables the cutting head to follow complex paths in three-dimensional space, resulting in the ability to cut intricate shapes and contours in various materials.

Four-axis cutting is also an option, TAPER CONTROL. This additional axis of movement, typically referred to as the A-axis or rotary axis, enables the cutting head to adjust its angle relative to the surface of the material being cut, compensating for taper and achieving perpendicular cuts even on materials with irregular surfaces or varying thicknesses.

![]() FIVE-AXIS WATERJET AND SIX-AXIS ROBOTIC SHAPE CUTTING

FIVE-AXIS WATERJET AND SIX-AXIS ROBOTIC SHAPE CUTTING

Waterjet cutting with robots is widely utilized across many industries including automotive, aerospace, construction, medical, food processing, and marine for precise and flexible cutting of materials including metals, composites, ceramics, meat, and fish.

The KMT OEM network offers 5 axis, six-axis, and seven-axis robotic systems, powered by KMT.

These advanced systems provide unparalleled accuracy and efficiency, enabling complex geometries and intricate designs to be easily executed.

KMT Waterjet has the most experience in custom-designed systems with the broadest range of waterjet pumps from 15hp-200hp, with operating pressure from 55,000psi to 90,000psi.

![]() COMBINATION WATERJET-SAW MACHINES

COMBINATION WATERJET-SAW MACHINES

Combining waterjet cutting with a disc saw blade, or SAWJET TABLES, offers stone manufacturers versatile cutting capabilities, enabling precise intricate designs with waterjet cutting and fast straight line cuts with the saw blade.

This integrated approach optimizes efficiency, reduces material waste, and delivers high-quality finished products in the stone industry, primarily used for cutting marble, granite, and other stone materials.

![]()

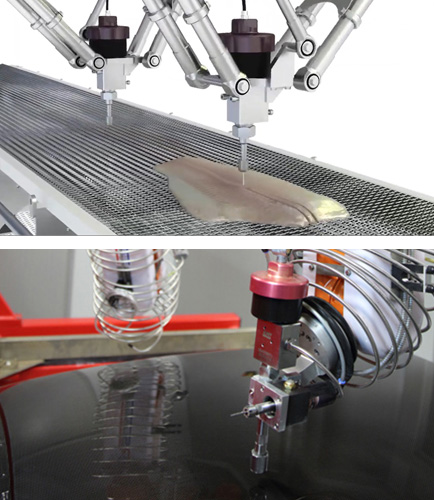

MULTIPLE CUTTING HEAD WATERJET SYSTEMS

Waterjet systems equipped with multiple cutting heads can simultaneously cut multiple parts or sections of material, increasing throughput and SIGNIFICANTLY reducing overall cutting time.

The KMT Waterjet cutting heads can be configured in various arrangements, including side-by-side, staggered, or nested configurations, to optimize water jet cutting efficiency and minimize material waste.

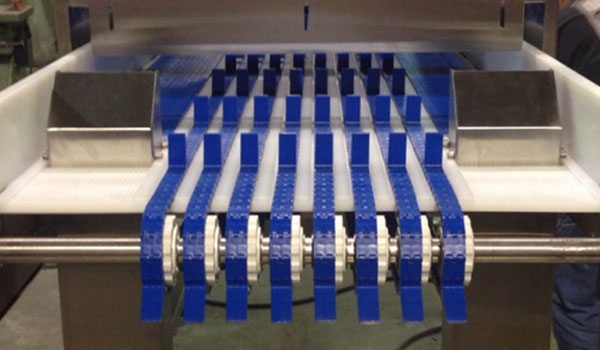

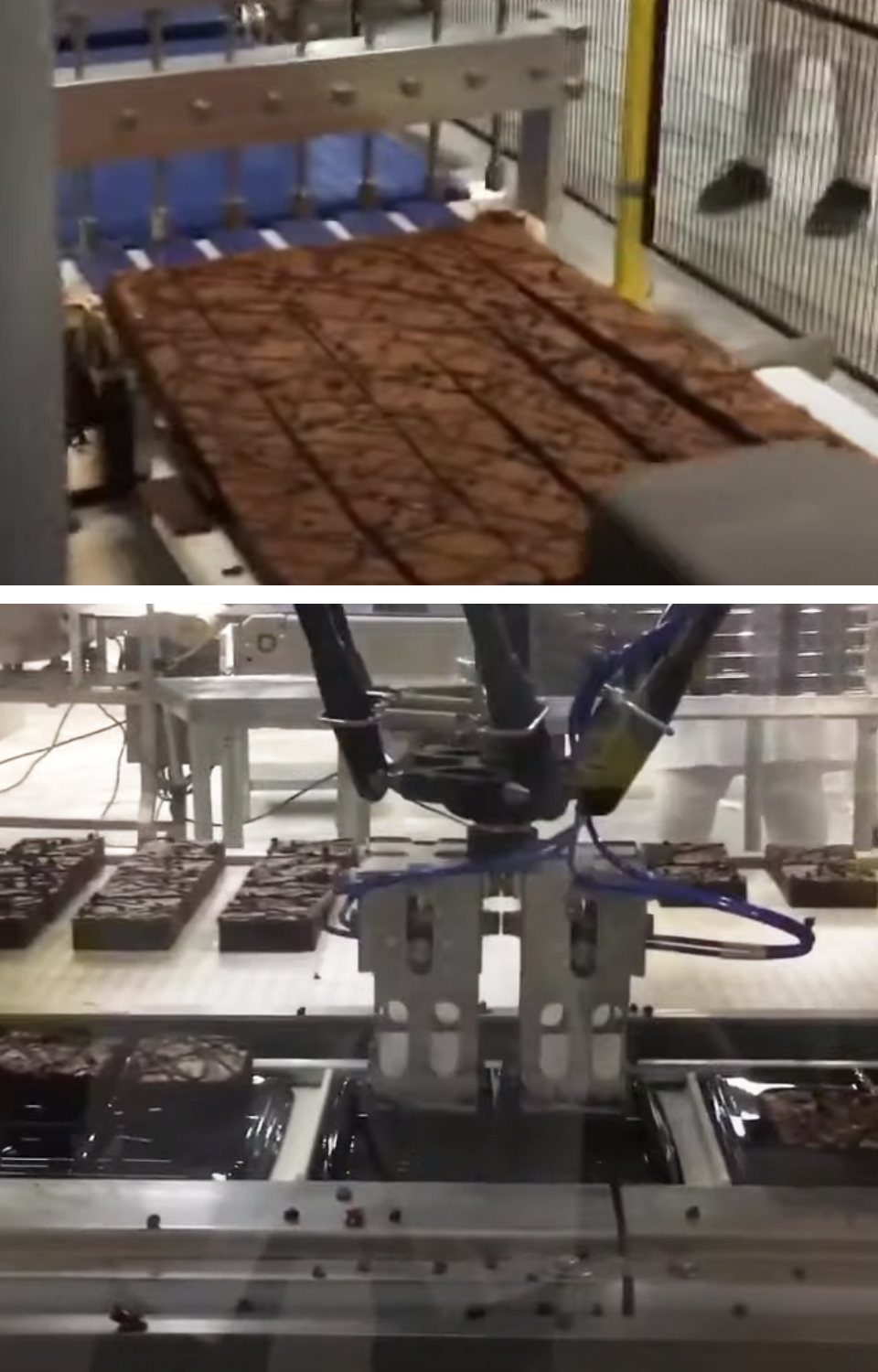

![]() CONVEYOR WATERJET SYSTEMS

CONVEYOR WATERJET SYSTEMS

A conveyor waterjet system is designed for continuous cutting of large sheets or rolls of material, including paper, glass wool, foam, and more.

Waterjet conveyor machines are also essential in the food industry, for precise cutting of various food items like fish, chicken, brownies, celery, and green beans. These machines automate the cutting process, ensuring consistent portion sizes, reduced product waste, and improved production efficiency while maintaining food safety and quality standards.

With their versatility and hygienic cutting capabilities, waterjet conveyor machines improve productivity in food processing operations across a wide range of protein, produce, and confectionery products.

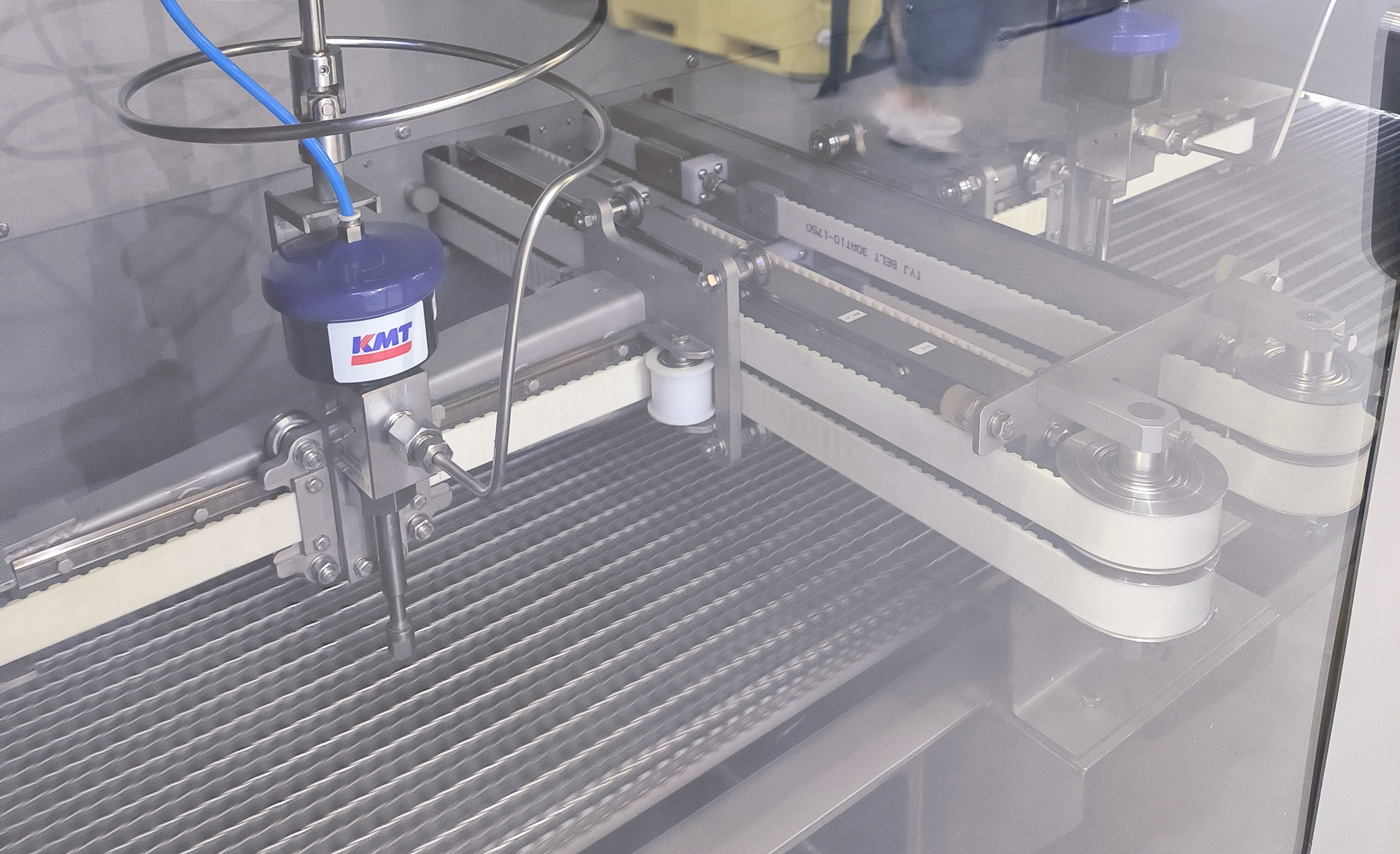

![]() SLITTER WATERJET TABLE

SLITTER WATERJET TABLE

A one-dimensional waterjet slitter, also known as a waterjet slitter or trimmer, is designed for linear cutting along one axis. It is typically used for trimming or slitting materials such as rubber, foam, textiles, or thin sheets of metal or plastic.

One-dimensional waterjet slitters have a simpler design compared to conveyor systems, as they only require linear motion along one axis. They are generally more compact and suitable for smaller-scale cutting operations.

![]() CUSTOM DESIGNED WATERJET SYSTEMS

CUSTOM DESIGNED WATERJET SYSTEMS

KMT, with over 180 global OEM manufacturers, offers the widest range of custom waterjet-designed machines, featuring KMT Waterjet pumps and components.

These machines serve industries including glass cutting, aerospace machining, building improvements, military, defense, and food processing, integrating features like vacuuming, cross-cutting, washing, vision scanners, weight control, packaging, and palletizing, integrated with precision cutting heads, robotic arms, and conveyor systems.

![]() CUSTOM WATERJET CUTTING AND PACKAGING PRODUCTS

CUSTOM WATERJET CUTTING AND PACKAGING PRODUCTS

With over 180 global OEM manufacturers, KMT offers the widest range of custom waterjet-designed machines, automated with packaging solutions, featuring KMT Waterjet pumps and components. These machines serve industries including glass cutting, aerospace machining, building improvements, military, defense, food processing, and more.

The KMT pumps and cutting heads are integrated with features like vacuuming, cross-cutting, washing, five-axis rotary machines for cutting pipe, vision scanners of protein, weight control, packaging and palletizing, precision cutting heads, robotic arms, six and seven axis machine, and conveyor systems. This specialization ensures efficient, precise material cutting, optimizing production workflows and maintaining quality standards, thus enhancing manufacturing processes across various sectors.

![]()

LARGE FORMAT CUTTING TABLES

Large cutting area formatted tables accommodate oversized materials and are ideal for industrial applications and large-scale projects.

Larger format tables allow cutting of multiple smaller parts simultaneously from a single large sheet. The larger format cutting process supports advanced software for designing complex patterns and maximizing material usage.

These systems are suitable for a wide range of industries, including aerospace, automotive, architecture, and manufacturing—

easily adapted for projects of varying sizes and complexities and easy integration with pre-existing digital designs and nesting programs.

WATERJET. A MACHINE FOR EVERY CUTTING NEED.

The KMT Waterjet global network of OEM (Original Equipment Manufacturer) integrators holds immense value in providing a complete waterjet cutting system anywhere in the world due to several key reasons:

Customization and Innovation: OEM integrators often work closely with KMT Waterjet to customize cutting solutions according to specific industry requirements or unique customer preferences. This collaborative approach fosters innovation and allows for the development of cutting-edge technologies that address evolving market demands effectively.

Localization: By partnering with OEM integrators across different regions, KMT Waterjet can ensure that their cutting systems are tailored to local needs, regulations, and standards. This localization enhances the adaptability and efficiency of the waterjet cutting systems in diverse markets.

Expertise and Support: OEM integrators bring their expertise in manufacturing, engineering, and customer support to the table. This ensures that customers not only get a high-quality waterjet cutting system but also receive comprehensive support services, including installation, training, and ongoing maintenance.

The Best Solutions for the Right Applications: Collaborating with the KMT Waterjet global OEM integrators have established relationships with local suppliers and distributors. This can result in the best solutions, faster delivery times, reduced logistics costs, and better inventory management, ultimately benefiting customers by ensuring timely access to spare parts and consumables.

Quality Assurance: KMT Waterjet maintains strict quality control standards across its global network of OEM integrators, ensuring that every waterjet cutting system meets or exceeds industry benchmarks for performance, reliability, and safety. This commitment to quality assurance instills confidence in customers regarding the durability and consistency of the equipment they invest in.

The KMT Waterjet global network of OEM integrators provides a strategic asset that amplifies the company’s capabilities to deliver comprehensive waterjet cutting solutions worldwide, encompassing not just cutting-edge technology but also localized support, expertise, and innovation.

Welcome to KMT Waterjet. To continue, please select a language from the options below.

HELP CENTER

Contact form

KMT Waterjet has global offices to assist you in your region. Contact us using the following form, and the message will be forwarded to the local office which can provide the best support.