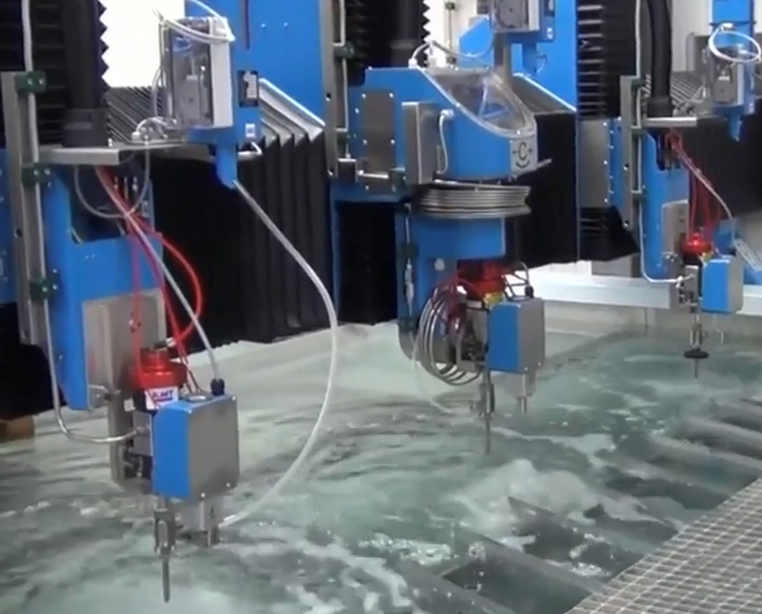

Waterjet systems with numerous cutting heads

Multiple cutting nozzles on waterjet machines, powered by KMT Waterjet, enhance productivity, faster turnaround times, reduce labor overtime, and lower costs per part.

The advantages of Waterjet machines using Multi-Heads.

The use of waterjet technology has grown significantly using customized waterjet machines, as manufacturers are seeking improved methods to cut faster but with the same floor space.

The use of waterjet technology has grown significantly using customized waterjet machines, as manufacturers are seeking improved methods to cut faster but with the same floor space.

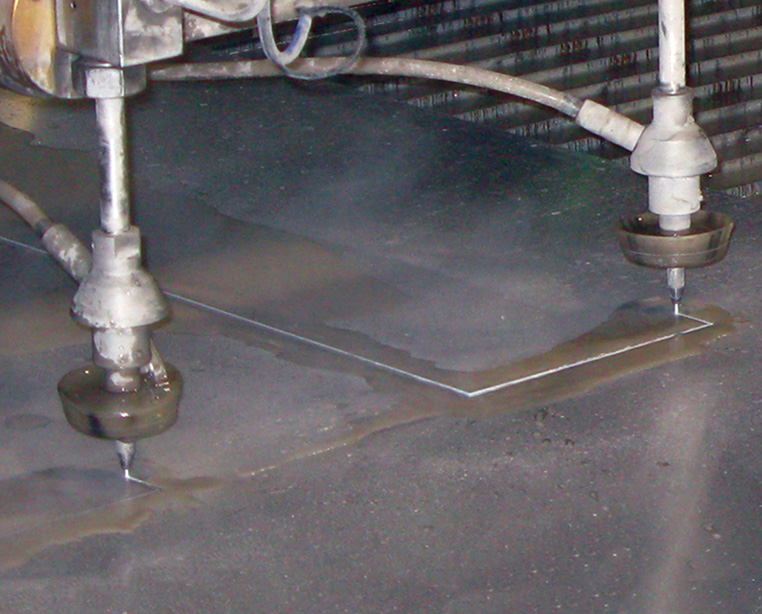

There are several advantages to a waterjet cut CNC table with two or more heads over single-cut systems:

Waterjet systems with numerous water jet heads cut a wide range of materials including metals, composites, plastics, foam, glass, stone, carpet, and a variety of food products.

Lower cost per part is achieved because fixed costs (e.g., operator, depreciation, overhead) can be spread across the increased number of produced parts per day, leading to lower total cost per part and expanded machine profitability.

The broadest network of global OEM integrators partners with KMT Waterjet to offer the best solutions in a waterjet system.

Custom waterjet machines including inline conveyors, from one-dimensional cuts to 6-axis robotic systems.

Powered by KMT intensifier pumps ranging from 50hp to 200hp and pressures from 60,000psi to 90,000psi, KMT pumps play a key role in determining the optimal number of cutting heads, boosting productivity, and minimizing expenses.

Multi-heads waterjet cutting improves productivity, efficiency, versatility, and quality while reducing lead times, optimizing material usage, and ensuring cost-effectiveness.

Improve Productivity by waterjet cutting

Waterjet machining two or more parts at the same time, reduces processing time, and enhances productivity, ideal for high-volume manufacturing.

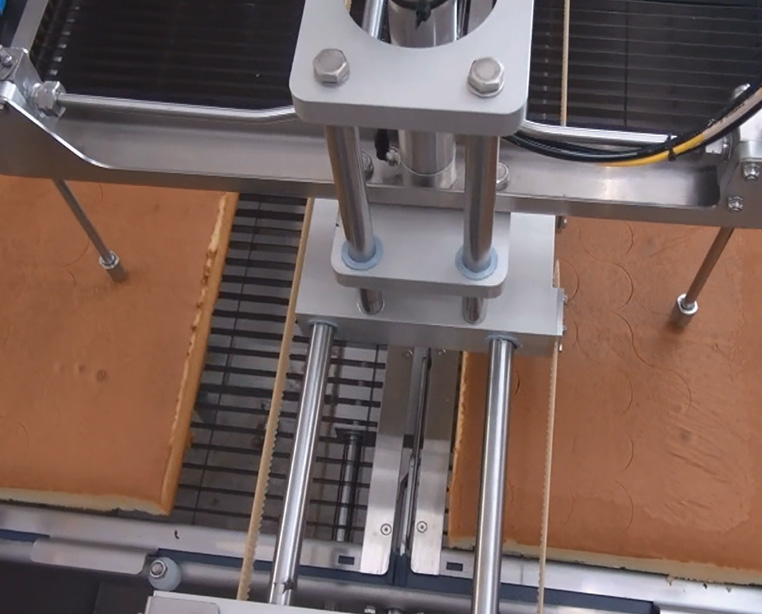

Waterjet Slitting Increase Throughput

Conveyors mounted two or more nozzles enhances consistency, accuracy, and material usage for efficient high-volume manufacturing.

Reduced Lead Times-Waterjet Technology

Customized waterjet systems reduce lead times, meet tight deadlines, and respond promptly to customer demands, powered by KMT pumps up to 90,000psi.

Cost Effectiveness-Reduce Overtime

Initial investment in multi-head waterjet systems yields long-term cost savings, boosted by double the productivity, efficiency, lower cost per part, and improved profitability.

Complete multi-nozzles Waterjet Machine and Table SYSTEMS, powered by KMT Waterjet

MULTI-CUTTING HEAD FAQ'S

Q: WHAT IS MULTIPLE HEAD WATERJET CUTTING? A: Traditionally, waterjet cutting involves a single head cutting one part at a time. However, with multiple cutting heads, the CNC water jet cutting machine can simultaneously cut multiple parts or sections. This upgrade to multiple cutting heads significantly enhances the efficiency and throughput of the cutting process, making it ideal for fabrication centers with high-volume production needs.

Trimming automotive headliners with four robotic "water only" heads

Shape Process Automation robotic slitting soft materials

Powered by KMT technology at 4.100 bar, 100hp pump