AEROSPACE SOLUTIONS FROM 5-AXIS TO ROBOTIC SYSTEMS

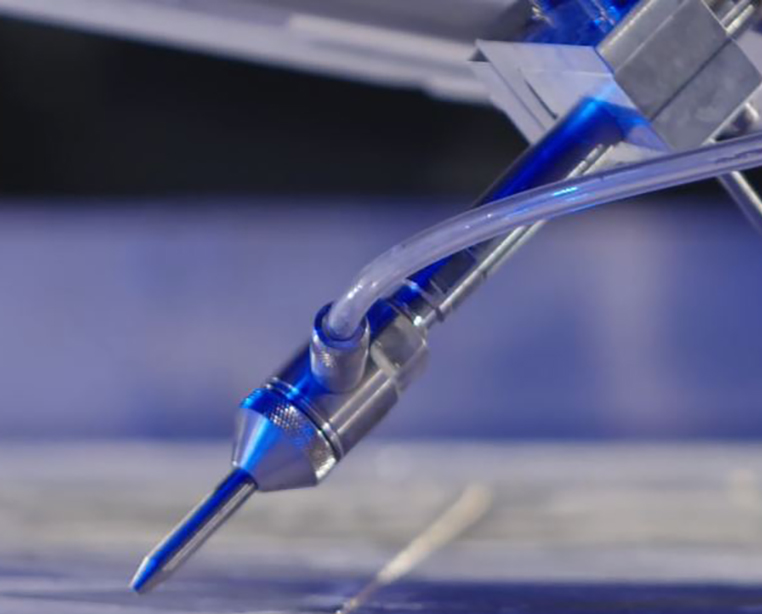

KMT Waterjet intensifier pump technology and abrasive waterjet cutting heads have been extensively used in aerospace for cutting titanium, Inconel, brass, aluminum, steel, and cutting composites from .039″/1 mm – 6″/150 mm.

waterjet cutting benefits

High-pressure water combined with an abrasive additive can cut through almost any material effectively and improve manufacturing productivity.

- Waterjet technology offers precision cutting for aerospace component manufacturing.

- 5-axis capabilities of waterjet cutting on three-dimensional shapes.

- Six-axis robotic waterjet cells for cutting complex angles and orientations.

- No heat-affected zones (HAZ) ensuring structural integrity.

VERSATILITY

The KMT Waterjet OEM network offers a complete line of waterjet table machines including five-axis waterjet to robotic integrated six-axis motion control.

FASTER

Waterjet stripping is up to 10x faster than chemical removal processes, saving time and money. Utrahigh-pressure water removes coatings without damaging materials.

PRECISION

Waterjet cutting enables precise metal cutting for various aerospace components. No Heat Affected Zones (HAZ), cracking or material delamination.

HIGH REPEATABILITY

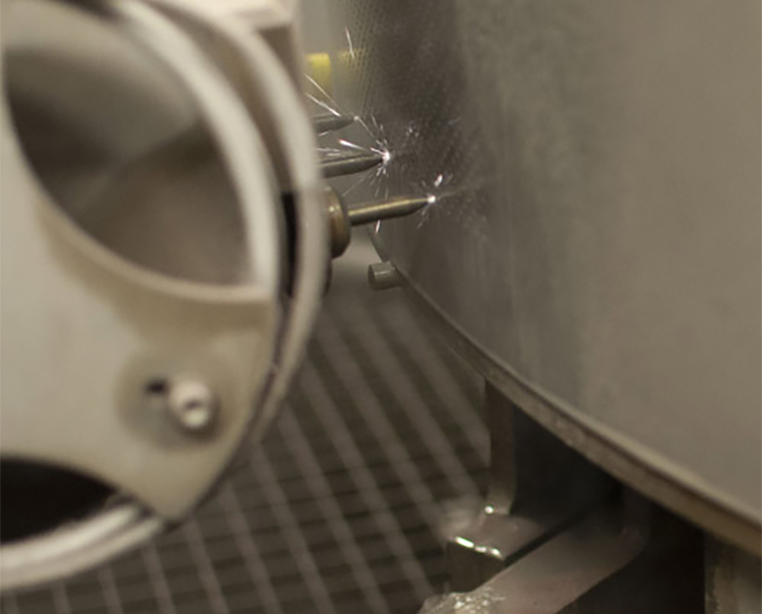

Waterjet hole drilling without stress on various metals (titanium, super alloys and more) can deliver a very accurate and tight mesh of holes.

KMT Global Network of OEM integrators offering complete Waterjet Systems for five-axis and six-axis robotic cell solutions.

AEROSPACE 5-AXIS CUTTING FAQ'S

Q: WHAT IS 5-AXIS WATERJET CUTTING? A: Five-axis waterjet cutting is an advanced machining to cut multiple angles simultaneously, allowing for intricate shapes and contours.

Full 3D Abrasive Waterjet Cutting

Technology by Water Jet Sweden/KMT Pumps

Each Water Jet Sweden FiveX (5 Axis waterjet cutting) machine system is a unique solution based on specific customer requirements.