The advantages of waterjet technology in the stone industry, including the benefits of five-axis saw/jet machines.

why does the stone industry use waterjet technology as the preferred machine tool for fabticating stone, marble, granite, quartzite, and more...

What is five-axis waterjet cutting, and how does it benefit the stone industry?

Five-axis waterjet cutting is an advanced machining technique that allows for cutting from multiple angles simultaneously, providing precision and versatility in shaping stone materials. KMT Waterjet pumps power the CNC machines, and integrates ultrahigh-pressure water up to 60,000psi into the CNC gantry or combination waterjet/saw disc blade table, ensuring consistent performance and reliability. Technical service support from KMT ensures optimal operation of the waterjet system.

Which stone materials can be cut using five-axis waterjet technology?

Five-axis waterjet cutting is suitable for a wide range of stone materials, including granite, marble, quartzite, and more. KMT Waterjet pumps deliver high-pressure water for precise cutting of the stone material, while technical service support ensures compatibility and efficiency with different stone types.

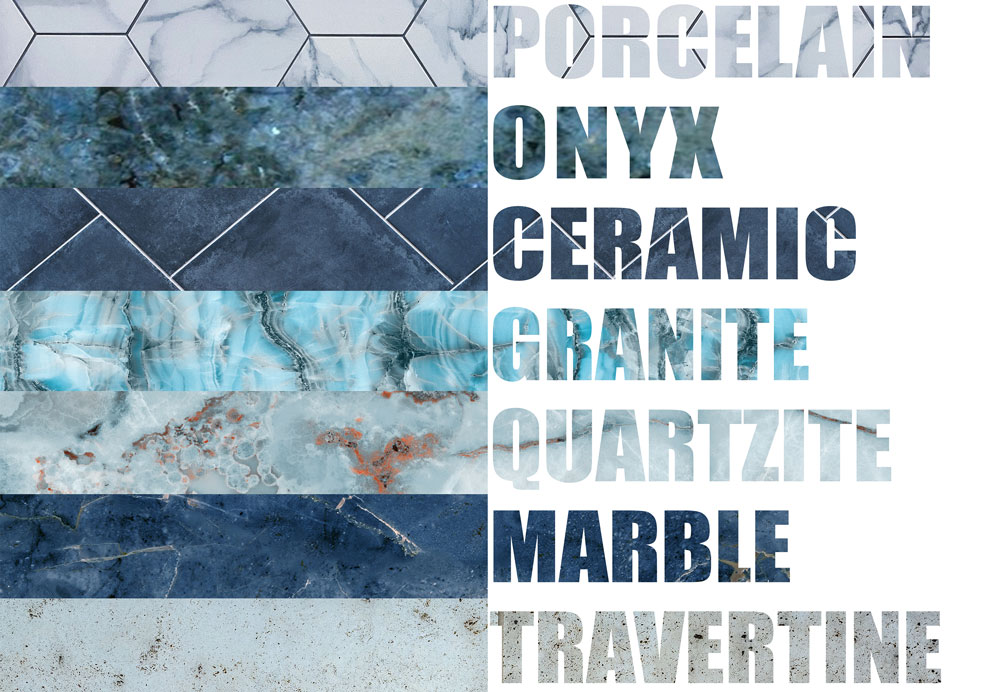

What materials for the stone industry have been successfully cut using five-axis waterjet technology?

The top 15 materials commonly used in the stone industry that are waterjet cut for mitering purposes using 5-axis waterjet cutting machines:

- Granite

- Marble

- Quartzite

- Travertine

- Slate

- Limestone

- Onyx

- Soapstone

- Sandstone

- Engineered stone (e.g., quartz, marble composite)

- Basalt

- Porcelain

- Terrazzo

- Agglomerate stone

- Semi-precious stones (e.g., quartzite, quartz)

What are the most frequently cut stone materials that have been successfully cut using five-axis waterjet technology?

In the stone industry, five-axis waterjet cutting is utilized to miter a variety of materials commonly used in fabrication. These materials include:

Granite: Renowned for its durability and aesthetic appeal, granite is frequently mitered using five-axis waterjet cutting. Waterjet cutting allows for precise miter cuts, ensuring a seamless fit for countertops, vanities, and other applications.

Marble: Waterjet cutting is used to miter marble, a luxurious and timeless stone prized for its elegance. With waterjet technology, intricate miter cuts can be achieved, preserving the natural beauty of marble for applications such as flooring, cladding, and decorative accents. Most of the floors with unique designs and patterns in the lobbies of hotels around the world have been waterjet cut products.

Quartzite: Known for its strength and resistance to heat and scratching, quartzite is often mitered using five-axis waterjet cutting. Waterjet technology enables precise miter cuts, enhancing the versatility of quartzite for countertops, backsplashes, and architectural features.

Travertine: Characterized by its unique texture and earthy tones, travertine is mitered with precision using five-axis waterjet cutting. Waterjet technology ensures accurate miter cuts, allowing travertine to be used for flooring, walls, and outdoor applications with seamless transitions.

Slate: Five-axis waterjet cutting is utilized to miter slate, a durable and low-maintenance stone with a distinctive layered appearance. Waterjet technology enables precise miter cuts, enhancing the natural beauty of slate for roofing, flooring, and wall cladding, many projects are powered by KMT Waterjet pumps and cutting components.

Limestone: With its range of colors and finishes, limestone is often mitered using five-axis waterjet cutting. Waterjet technology allows for accurate miter cuts, making limestone suitable for countertops, flooring, and architectural elements with seamless joints.

Onyx: Prized for its translucent quality and striking veining, onyx is mitered with precision using five-axis waterjet cutting. Waterjet technology enables intricate miter cuts, enhancing the dramatic beauty of onyx for countertops, flooring, wall coverings, backsplashes, and decorative features.

Soapstone: Waterjet cutting is employed to miter soapstone, a natural stone known for its heat resistance and timeless appeal. With waterjet technology, precise miter cuts can be achieved, making soapstone ideal for countertops, sinks, and fireplace surrounds.

These materials are frequently used in the fabrication of countertops, vanities, flooring, and architectural elements, among other applications. These materials vary in hardness, texture, and appearance, but the precision and versatility of five-axis waterjet cutting ensure seamless miter cuts for a wide range of stone types in the industry.

The precision and versatility of 5-axis waterjet cutting machines allow for intricate miter cuts, bevels, and contours to be achieved with accuracy and efficiency in the stone industry.

How does five-axis waterjet cutting compare to traditional stone cutting methods?

Five-axis waterjet cutting offers greater precision, flexibility, and efficiency compared to traditional stone cutting methods especially for mitering up to 55 degrees for intricate designs, including curves and angles.

What are the advantages of using KMT Waterjet pumps for stone cutting applications?

KMT Waterjet pumps offer superior performance, reliability, and efficiency for stone cutting applications. They provide high-pressure water for precise cutting, resulting in clean edges and minimal material waste. Technical service support from KMT Waterjet in over 100 countries ensures uninterrupted operation and maintenance of the waterjet system.

Can five-axis waterjet cutting be used for intricate designs and patterns in stone materials?

Five-axis waterjet cutting is ideal for creating intricate designs, patterns, and custom shapes in stone materials.

How does KMT Waterjet’s technical service support enhance the performance of five-axis waterjet cutting systems?

KMT Waterjet’s technical service support provides comprehensive assistance for installing, operating, and maintaining five-axis waterjet cutting systems. This ensures optimal performance, reliability, and longevity of the equipment, allowing stone fabricators to maximize productivity and efficiency.

What maintenance procedures are required for KMT Waterjet pumps used in five-axis waterjet cutting systems?

Regular maintenance is essential for ensuring the longevity and performance of KMT Waterjet pumps in five-axis waterjet cutting systems. KMT’s technical service support offers guidance on maintenance procedures, including pump inspection, lubrication, and parts replacement, to minimize downtime and optimize performance.

What are the environmental benefits of using five-axis waterjet cutting technology with KMT Waterjet pumps in the stone industry?

environmental benefits of using five-axis waterjet cutting technology with KMT Waterjet pumps in the stone industry?

Five-axis waterjet cutting technology with KMT Waterjet pumps offers several environmental benefits compared to traditional stone cutting methods. It generates minimal dust, noise, and vibration, reducing environmental impact and improving air quality in stone fabrication facilities. KMT’s technical service support ensures that waterjet cutting systems are optimized for maximum efficiency and environmental sustainability.

Can KMT Waterjet pumps be integrated with existing stone cutting equipment and workflows?

KMT Waterjet pumps can be seamlessly integrated with existing stone cutting equipment and workflows to enhance productivity and efficiency. KMT’s technical service support offers guidance and expertise in system integration, ensuring smooth operation and compatibility with existing processes.

How does KMT Waterjet’s technical service support address common issues and challenges encountered during stone cutting operations?

KMT Waterjet’s globally located technical service support provides timely –>FAST<– assistance and troubleshooting for common issues and challenges encountered during stone cutting operations. Whether it’s nozzle clogging, abrasive flow issues, or pump maintenance, KMT’s experts offer solutions to keep the waterjet system running smoothly.

What training programs are available for operators and technicians using five-axis waterjet cutting systems with KMT Waterjet pumps?

KMT Waterjet offers comprehensive training programs for operators and technicians using five-axis waterjet cutting systems with KMT Waterjet pumps. These programs cover equipment operation, maintenance, troubleshooting, and safety protocols, ensuring that personnel are proficient in operating and maintaining waterjet cutting systems for stone fabrication applications.

How does KMT Waterjet’s technical service support ensure the compatibility of waterjet cutting systems with different stone materials?

KMT Waterjet’s technical service support includes material testing and compatibility assessments to ensure that waterjet cutting systems perform optimally with different stone materials. This ensures consistent cutting quality and efficiency across a wide range of stone types and thicknesses.

These FAQs address common inquiries about five-axis waterjet cutting technology in the stone industry, emphasizing the role of KMT Waterjet pumps and technical service support in ensuring optimal performance, reliability, and efficiency.