500V Abrasive Hopper storage system

The KMT Waterjet metering abrasive hopper will hold up to 600 pounds, with reloading garnet while waterjet cutting.

METAL | STONE | GLASS

KMT Waterjet 500V Series Abrasive Hopper - Continuous Level Monitoring for an Efficient Production Process

- Abrasive Flow Monitoring Saves Time and Costs

Our 500 V HOPPER precisely monitors the availability of sufficient abrasive closely during the entire cutting process and pneumatically transfers it to the onboard metering device.

This protects your valuable material from damage and saves unnecessary costs and time.

Its concept assures process stability, security and a very high degree of reliability. - Abrasive Low Level Sensor

The 500 V HOPPER provides all features to stabilize the cutting process when connected to a centralized control system.

The abrasive delivery system features a normally closed proximity switch sensor which indicates when the abrasive content reaches a low level.

This feature provides the capability to integrate the signal into the waterjet system controller and notifies the operator when it’s time to refill the abrasive.

When used in one or multiple shift operation of automated cutting systems, the 500 V HOPPER contributes to the economical use of the entire waterjet cutting system.

FEATURES:

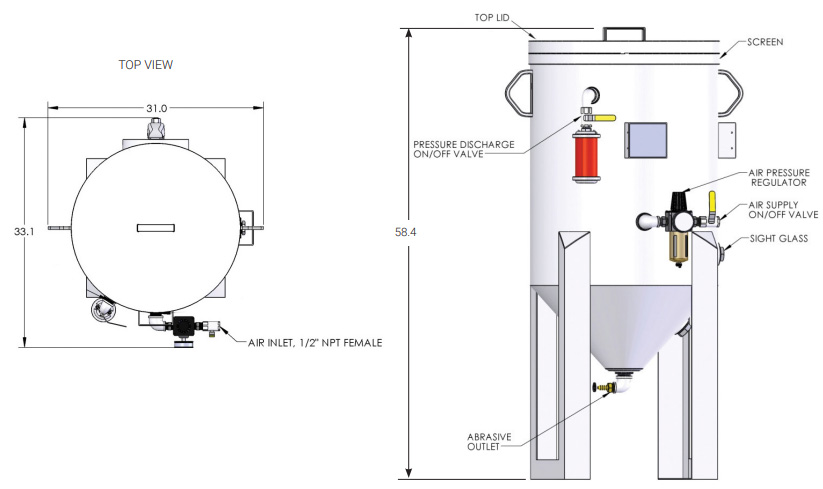

- Screened loading area allows for individual bags to be loaded thorough the screen on top of the bulk hopper.

- Storage tank holds up to 600 pounds of abrasive.

- Low abrasive level sensor—prevents running out of abrasive while cutting.

- Air regulator and 2 way valve controls the pressure and on/off capabilities.

Reliability & Low Maintenance at a LOW COST

The 500 V HOPPER is  just one link in the KMT quality abrasive management system for waterjet cutting.

just one link in the KMT quality abrasive management system for waterjet cutting.

Use with the FEEDLINE V Electronic Metering System to provide a constant metered flow of abrasive and

optimize abrasive consumption.

The patented design of the IDE® Diamond Cutting Nozzle provides a sharper, faster cutting stream which will

further reduce abrasive use and maximize efficiency for lower operating cost.

Advantages of the KMT 500 V SERIES HOPPERS

- Easy to Maintain

Easy-access screened loading area blocks out most all contaminants and allows for individual 100 lb.

bags to be loaded thorough the screen on top of the bulk hopper. Holds up to 600 lbs.

at a time!

- SAVES TIME AND MONEY

Our 500 V HOPPER precisely monitors the availability of sufficient abrasive closely during the entire cutting process.

This protects your valuable material from damage and saves unnecessary costs and time.

- KMT GENUINE SERVICE

KMT Genuine Service is closer than you think and can install your new abrasive hopper and fill your abrasive orders for you.

Call +1-800-826-9274, press 2 or email: kmtgenuineservice@kmtwaterjet.com