Custom waterjet cutting-FAQs about CNC customized solutions.

Waterjet cutting technology when integrated with KMT Waterjet and Shape Process Automation robotic waterjet cells, picking and packaging machines, offers a versatile and efficient solution for various industries.

Custom waterjet cutting, whether in automotive manufacturing, food production, or aerospace engineering, water jet cutting enhances efficiency, accuracy, and overall productivity.

The following FAQ offers information about robotic systems combining waterjet technology with picking and packaging into one automation unit.

What are robotic systems that combine waterjet cutting and packaging? These systems integrate waterjet cutting technology with automated picking and packaging, creating a seamless solution for various production processes.

These systems integrate waterjet cutting technology with automated picking and packaging, creating a seamless solution for various production processes.

What industries benefit from these integrated robotic systems? Industries such as food production, automotive, aerospace, and medical manufacturing benefit from these systems due to their precision and efficiency.

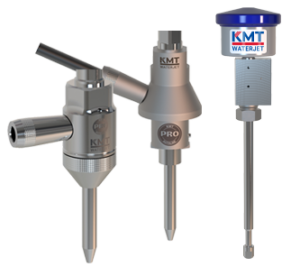

What is the role of KMT Waterjet in these robotic systems? KMT Waterjet provides ultrahigh-pressure pumps, cutting nozzles, valves, fittings, and tubing, ensuring high-performance cutting and reliable system integration.

How do these systems enhance food production? Manufactured by Shape Process Automation, they design robotic waterjet systems that will ensure cleanliness, safety, and quality while minimizing waste and emphasizing environmental responsibility, crucial for meeting regulatory and consumer demands.

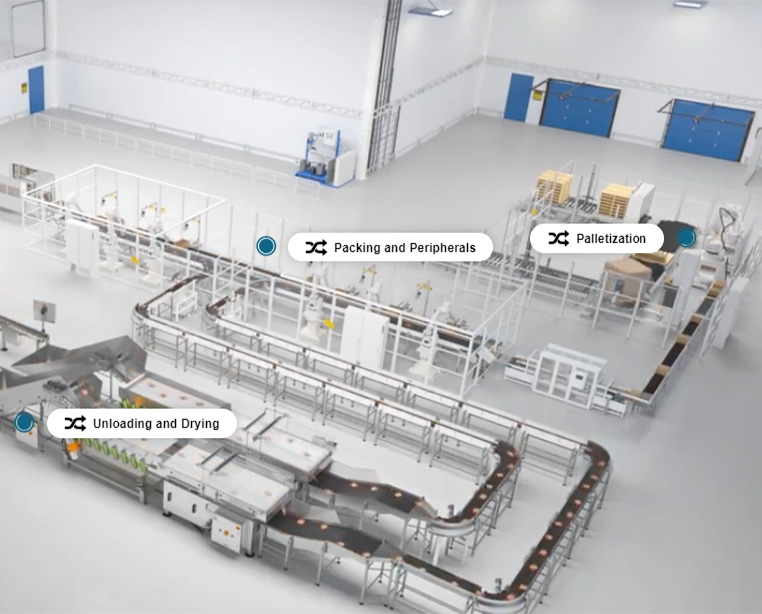

What is total system integration in the context of these robotic systems? Total system integration involves combining standard equipment into a complete, smoothly functioning solution that handles cutting, processing, conveyance, material handling, palletizing, and packaging.

How do these systems improve efficiency in manufacturing? By automating the entire process from waterjet cutting with six-axis robotic cells, to packaging, these systems reduce manual labor, increase precision, and streamline production workflows.

What is the advantage of true six-axis waterjet systems? True six-axis waterjet systems provide the precision and dexterity needed for intricate, highly contoured part production with exceptional complexity.

How does micro-waterjet cutting technology work? Micro-waterjet cutting technology uses fine abrasives to cut very hard materials into near-2D geometries with high precision, suitable for medical and aerospace applications.

What are the environmental benefits of using these integrated systems? These systems minimize waste and reduce energy consumption, aligning with environmental responsibility and sustainability goals.

with environmental responsibility and sustainability goals.

How do these systems handle product conveyance and material handling? Integrated conveyance and material handling components move products efficiently from one area to another, ensuring a smooth production flow.

What is the importance of automation in food manufacturing? Automation ensures consistent quality, enhances cleanliness and safety, and meets rising regulatory and consumer demands for food products.

How are KMT Waterjet pumps integrated into these systems? KMT Waterjet pumps are integrated to provide consistent, ultrahigh-pressure water streams for precise cutting in various manufacturing processes. KMT also provides preventive maintenance support in over 70 countries to ensure that the waterjet pump is operating at peak performance with minimal downtime.

What is the significance of packaging in these robotic systems? Automated packaging ensures that products are securely packed, maintaining quality and reducing manual handling, which increases overall efficiency, as a continuous flow through the product manufacturing process.

Can these systems be customized for specific manufacturing needs? Yes, KMT Waterjet’s global OEM network can custom design these systems to meet specific requirements of various industries around the world.

How do these systems ensure product quality and safety? By integrating precise cutting and automated handling, these systems maintain high standards of product quality and safety throughout the production process.

What are the advantages of using waterjet technology in these systems? Waterjet technology offers precise, clean cuts without heat distortion, making it ideal for a wide range of materials and applications.

How does automation help in reducing production costs? Automation reduces labor costs, minimizes errors, and increases production speed, leading to overall cost savings in manufacturing.

What are the key components of these integrated systems? Key components include KMT Waterjet pumps, cutting nozzles, valves, fittings, tubing, conveyance systems, material handling equipment, and automated packaging machines.

integrated systems? Key components include KMT Waterjet pumps, cutting nozzles, valves, fittings, tubing, conveyance systems, material handling equipment, and automated packaging machines.

Why should manufacturers consider investing in these robotic systems? Investing in these systems enhances production efficiency, ensures high-quality output, reduces waste, and aligns with environmental and regulatory requirements, providing a competitive edge in the market.

Waterjet cutting with custom six-axis robotic cell powered by KMT Waterjet stands out as a highly efficient and precise method for diverse industrial applications. By integrating advanced technology with robust engineering solutions, KMT Waterjet delivers unparalleled performance in cutting various materials.

Whether enhancing automotive manufacturing processes, ensuring consistent food production, or achieving intricate cuts in the aerospace and medical fields, KMT Waterjet systems provide reliable and innovative solutions.