CUSTOM DESIGNED MACHINES POWERED BY KMT Waterjet-FAQs

Waterjet technology is the preferred machine tool in MOST EVERY industry. Here are some common FAQ's about CUSTOM DESIGNED waterjet machines, powered by KMT Waterjet.

Custom-designed CNC tables are available worldwide with the KMT OEM network of integrators.

Waterjet cutting technology, especially when powered by KMT Waterjet, offers a versatile and efficient solution for various industries.

From cutting intricate medical parts to processing food items like lettuce and desserts, the applications are vast and impactful.

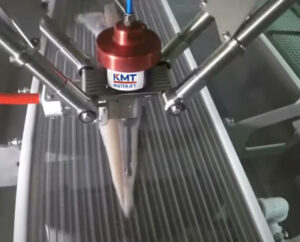

Waterjet technology is powered by high-pressure water jet stream up to 90,000psi, often mixed with an abrasive garnet, to achieve precise cuts in a wide range of materials.

Whether in automotive manufacturing, food production, or aerospace engineering, waterjet cutting enhances efficiency, accuracy, and overall productivity.

The following FAQ section provides detailed insights into the capabilities and benefits of waterjet cutting with custom CNC machines, powered by KMT Waterjet.

What industries benefit from custom CNC waterjet machines?

Custom CNC waterjet machines serve diverse industries, including automotive, aerospace, medical, food production, paper, glass, and insulation for home and commercial development.

Custom CNC waterjet machines serve diverse industries, including automotive, aerospace, medical, food production, paper, glass, and insulation for home and commercial development.

How does waterjet cutting improve food production operations?

Waterjet systems ensure precise cutting, enhancing efficiency, reducing waste, and guaranteeing consistent portioning, crucial for large-scale food production.

How does waterjet cutting work in the food industry? Custom waterjet systems precisely cut meats, fish, vegetables, and baked goods, ensuring consistent portioning and reducing waste.

What is field waterjet harvesting? Field waterjet harvesting uses horizontal waterjet cutting jets to increase yield and product shelf life by adjusting cut height for uneven beds, ensuring efficient harvesting.

What are the advantages of using waterjet cutting in automotive manufacturing? Robotic waterjet cutting enhances manufacturing processes by improving efficiency and accuracy in producing automotive parts.

What are six-axis robotic waterjet cells? Six-axis robotic waterjet cells are advanced systems that can cut complex shapes in automotive materials like composites, glass, carpets, and headliners with high precision.

How does waterjet trimming work? Waterjet trimming is ideal for materials that may distort with other methods, offering precision and maintaining material quality.

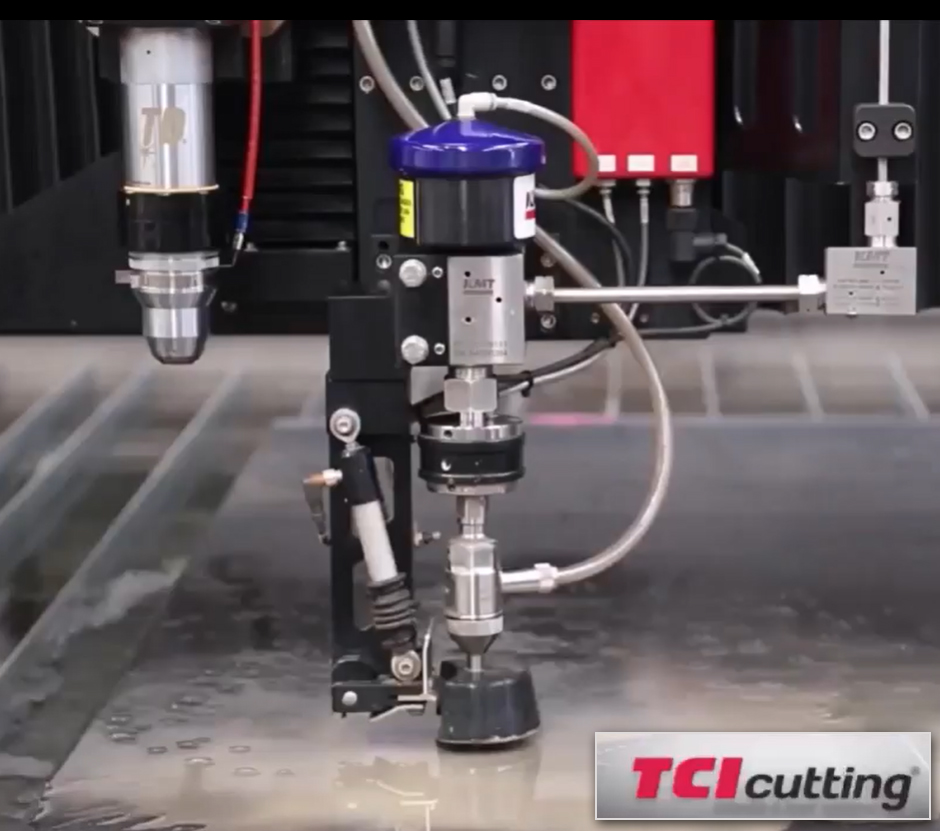

How do combination waterjet/plasma cutting machines work? These machines integrate the benefits of waterjet and plasma cutting technologies, offering a versatile solution for various industrial cutting needs, all in one machine.

What are the benefits of combining waterjet and plasma cutting technologies? Combining these technologies provides versatility, leveraging the strengths of both methods to handle a wide range of industrial cutting applications.

Can waterjet cutting be used for insulation materials? Yes, waterjet cutting systems for insulation foam have replaced slow, costly manual cutting methods, saving up to 95% of the time and significantly reducing costs.

What is micro-waterjet cutting? Micro-waterjet cutting is a precise technology used to cut very hard materials into near-2D geometries, commonly used in the medical and aerospace industries.

cutting? Micro-waterjet cutting is a precise technology used to cut very hard materials into near-2D geometries, commonly used in the medical and aerospace industries.

What benefits do KMT Waterjet pumps offer? KMT Waterjet pumps provide high-pressure streams for precise cutting, and our network of over 180 OEM integrators offers tailored solutions with top engineering expertise.

How does waterjet cutting compare to other cutting methods? Waterjet cutting is preferred for materials susceptible to distortion from heat cutting, as it provides precise cuts without affecting the material’s integrity.

Why choose KMT Waterjet for custom CNC machines? KMT Waterjet’s extensive experience, network of OEM integrators, and advanced ultrahigh-pressure pumps ensure high-quality, tailored solutions for various cutting needs.

Waterjet cutting with custom CNC machines powered by KMT Waterjet stands out as a highly efficient and precise method for diverse industrial applications.

By integrating advanced technology with robust engineering solutions, KMT Waterjet delivers unparalleled performance in cutting various materials.

Whether enhancing automotive manufacturing processes, ensuring consistent food production, or achieving intricate cuts in the aerospace and medical fields, KMT Waterjet systems provide reliable and innovative solutions.