We and selected third parties use cookies or similar technologies for technical purposes and, with your consent, for other purposes. You can consent to the use of such technologies by using the “Accept” button, by closing this notice, by scrolling this page, by interacting with any link or button outside of this notice or by continuing to browse otherwise.

- CUTTING SOLUTIONS

- PRODUCTS

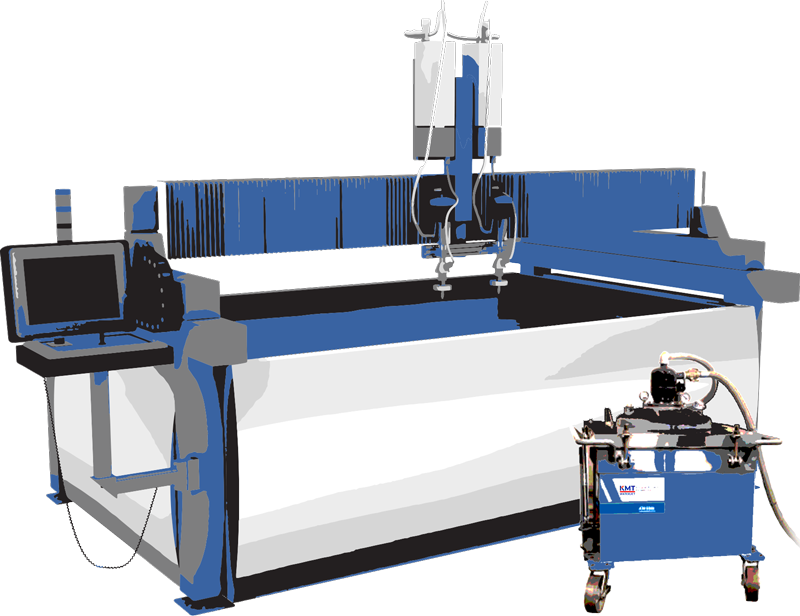

COMPLETE SYSTEMS

KMT waterjet OEM partner machines are powered by KMT pumps ranging from 6.200 bar to 3.800 bar, with installations available in over 100 countries.

PRO 6.200 bar Pumps – World’s Fastest Waterjet

The KMT Streamline PRO® 6.200 bar Waterjet Pumps will significantly increase production by cutting in less time and use up to 50% less abrasive to produce the Lowest Cost Per Part! The PRO pump is available in three horse-powers for a wide range of cutting applications: 125 and 60 PS

ABRALINE IV Abrasive Hopper

Precisely monitors abrasive feed usage during entire cutting process. Designed for large cutting machines which operate continuously and with multiple cutting heads. Capacity – 1.000 kg

STREAMLINE® SL-VI 4.100 bar Pumps

KMT Waterjet SL-VI Pumps have decades of proven performance and are considered the Industry Workhorse! The SL-VI Series of pumps are available in: 15, 30, 50 und 100 PS

ABRALINE V Abrasive Hopper

Precisely monitors abrasive feed usage during entire cutting process. Designed to sufficiently ensure the abrasive feed for average cutting needs. Capacity – 425 kg

KMT CLASSIC V-Drive 3.800 bar Energy Saving Pump

The STREAMLINE® CLASSIC with V-Drive combines the KMT proven intensifier concept with energy saving drive and control technology for energy savings and efficient waterjet cutting. Equipped with a speed-controlled motor drive, the CLASSIC V-Drive satisfies any criteria specifying an energy saving machinery.

FEEDLINE V Abrasive Feeder

Optimized abrasive consumption for customized applications. Controlled through a central CNC controller or a potentiometer, the FEEDLINE V supplies the cutting nozzle with the optimized flow of abrasive, saving material and costs.

ATS Abrasive Removal Systems

Never shut down production for tank clean outs again. The all new ATS 2200 or 4400 is the perfect way to improve your waterjet operations.

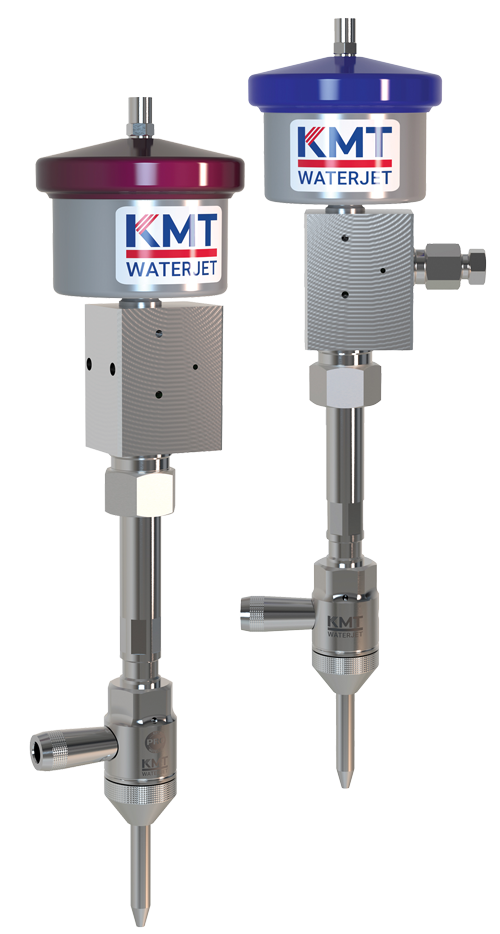

IDE® Diamond Cutting Heads

The KMT Waterjet IDE® (Integrated Diamond Eductor) One-piece Assembly Cutting Head is rated for pressures from 4.100 bar to 6.200 bar and is a waterjet nozzle breakthrough in simplicity & peak performance.

AUTOLINE® Cutting Heads

The self-aligning components of the KMT AUTOLINE® 4.100 bar and 6.200 bar cutting heads provide true, perfect alignment to extend the life of focusing tubes and mixing chambers.

AQUALINE® Water-only Cutting Heads

PROVEN PERFORMANCE AT EXTREME PRESSURES! Our AQUALINE® pure water pneumatic valves have gained an industry-wide reputation for being among the quickest and the most reliable pure water cutting heads under extreme working conditions.

KMT CUT Calculator App

Compare 6.200 bar vs. 4.100 bar cutting and see how much faster you get the job done and at a lower cost per part! The KMT Waterjet Cut Calculator 2.0 App incorporates 25 materials, offers a wider range of substrate thicknesses, horsepower, orifice size, and abrasive rates.

ARA 3.800 bar Pump

The Ara™ high-pressure pump meets all essential requirements for successful, economical and seamless operation of a waterjet cutting system. The highly reliable “SSEC” intensifier design is one of the key features of the AraTM pump.

- COMPLETE SYSTEMS

- ABRALINE IV Abrasive Hopper

- PRO 6.200 bar Pumps

- ABRALINE V Abrasive Hopper

- SL-VI 4.100 bar Pumps

- FEEDLINE V Meter

- Classic V-Drive 3.800 bar Pump

- ATS Abrasive Removal Systems

- ARA 3.800 bar Pump

- IDE Diamond Cutting Head

- AUTOLINE Cutting Head

- AQUALINE Water-only Cutting Head

- Cut Calculator App

- APPLICATIONS/INDUSTRIES

FAQ - Abrasive Removal Machines for Waterjet Cutting Systems and Recycling Abrasive Garnet Advantages and Disadvantages

Here are frequently asked questions that KMT Waterjet has received about using the KMT ATS abrasive removal machines for waterjet cutting systems:

What is an abrasive removal machine for waterjet cutting systems?

The KMT ATS 2200 and ATS 4400 extract the used abrasive like garnet from waterjet tanks, improving cleaning and operational efficiency.

How does the KMT abrasive removal machine work?

KMT’s machine removes used abrasive from waterjet tanks, separating it for disposal or recycling through suction or filtration.

Why is it necessary to remove abrasive material from the waterjet tank?

The KMT ATS vacuum system removes used abrasive to maintain cutting efficiency and prolong equipment lifespan, essential for operations.

Regular removal of accumulated abrasive prevents cutting performance issues and equipment damage.

What are the primary components of an abrasive removal machine?

Abrasive removal machines consist of suction pumps, filtration systems, collection bins, and control mechanisms for efficient disposal.

How often should abrasive material be removed from the waterjet tank?

The frequency of abrasive removal varies based on factors like cutting volume, material type, and conditions, often after significant cutting jobs.

Can abrasive material be recycled after removal from the waterjet tank?

This is a great question, that is explored in depth as you review the FAQ in this document.

What are the benefits of recycling abrasive material from waterjet cutting operations?

Recycling abrasive material reduces costs, waste, and promotes eco-friendly practices, offering businesses both financial and environmental benefits.

How is the KMT abrasive removal machine different than using manual labor to shovel garnet abrasive out of a waterjet tank into a cloth container for disposal?

Safety Risks: Entering the waterjet tank and manually shoveling abrasive material poses significant safety risks to employees.

They may be exposed to abrasive particles, and slippery surfaces, increasing the likelihood of accidents and injuries.

Health Hazards: Without proper protection, handling garnet abrasive can lead to health hazards like skin irritation, respiratory problems, and eye injuries.

Time-Consuming and Labor-Intensive: Manual garnet removal from waterjet tanks is laborious, time-consuming, and inefficient, leading to increased labor costs.

Potential Damage to Equipment: Using shovels or tools to scoop abrasive from waterjet tanks risks damaging tank lining, equipment, or accessories.

Accidental contact with abrasive residues can lead to wear, tear, and leaks, necessitating costly tank repairs or replacements.

How can I ensure the proper operation and maintenance of an abrasive removal machine?

Operating and maintaining abrasive removal machines involves following KMT Waterjet guidelines, regular inspections, cleaning filters, and scheduling maintenance checks.

Integrating KMT abrasive removal machines with existing waterjet tables.

Can abrasive removal machines be integrated into existing waterjet cutting setups?

KMT Waterjet abrasive transfer vessels are garnet removal machines designed for compatibility with existing setups, offering flexibility in configurations.

Do abrasive removal machines require specialized training to operate?

Operators require training on machine operation, safety protocols, and maintenance to ensure efficient and safe abrasive removal machine operation.

How do abrasive removal machines contribute to overall efficiency in waterjet cutting operations?

Abrasive removal machines minimize downtime, optimize cutting performance, and enhance efficiency by streamlining cleaning processes and maintaining clean cutting environments.

Are abrasive removal machines suitable for different types of waterjet cutting machines?

KMT Waterjet abrasive removal machines are versatile and compatible with various waterjet cutting machine types and brands.

What factors should I consider when selecting an abrasive removal machine for my waterjet cutting system?

Consider cutting volume, abrasive type, filtration efficiency, maintenance, and compatibility with existing equipment when choosing an abrasive removal machine.

Explore FAQs on the pros and cons of recycled garnet abrasive in waterjet machines along with their answers below.

What is recycled garnet abrasive, and how is it obtained?

Recycled garnet abrasive is reused material collected from waterjet cutting, processed, and prepared for subsequent cutting operations.

What are the advantages of using recycled garnet abrasive in a waterjet machine?

Advantages include cost savings, reduced waste, environmental sustainability, and comparable cutting performance to fresh abrasive material.

Does recycled garnet abrasive offer cost savings compared to purchasing fresh abrasive material?

Using recycled garnet abrasive typically offers significant cost savings as it eliminates the need to purchase new abrasive material for each cutting job.

How does using recycled garnet abrasive contribute to environmental sustainability?

Recycling garnet abrasive minimizes waste, and environmental impact, and conserves resources by extending abrasive material lifespan.

What are the potential disadvantages of using recycled garnet abrasive in a waterjet machine?

Disadvantages may include decreased cutting efficiency over multiple reuse cycles, increased risk of nozzle clogging or abrasive contamination, and additional processing requirements for recycling.

Does recycled garnet abrasive require additional processing before reuse in a waterjet machine?

Recycled garnet abrasive may require additional processing, such as screening, cleaning, and drying, to remove impurities and ensure optimal cutting performance.

How does the quality of recycled garnet abrasive impact cutting performance?

The quality of recycled garnet abrasive, including particle size distribution, cleanliness, and hardness, directly affects cutting performance and WILL require careful monitoring and adjustment.

Are there any specific precautions or considerations when using recycled garnet abrasive in a waterjet machine?

Waterjet operators should monitor abrasive performance, nozzle condition, and cutting quality closely when using recycled garnet abrasive to ensure optimal results and minimize potential issues.

Does the recycling process affect the physical properties of garnet abrasive?

The recycling process may alter some physical properties of garnet abrasive, such as particle size distribution and hardness, which can impact cutting performance and efficiency.

How does the lifespan of recycled garnet abrasive compare to that of fresh abrasive material?

The lifespan of recycled garnet abrasive may vary depending on factors such as processing quality, cutting conditions, and abrasive wear, but it can typically be reused multiple times before replacement.

Where can I obtain recycled garnet abrasive for use in my waterjet machine?

Recycled garnet abrasive may be obtained from specialized suppliers or through in-house recycling processes, depending on availability and specific needs.

Using recycled garnet abrasive in a waterjet system can offer cost savings and environmental benefits, but it also carries certain risks, especially when dealing with expensive equipment.

Here are ten top risks associated with using recycled garnet abrasive in an expensive waterjet system:

Reduced Cutting Performance: Recycled garnet abrasive may have degraded cutting properties compared to fresh abrasive, leading to decreased cutting efficiency and precision.

Nozzle Clogging: Impurities  or contaminants present in recycled garnet abrasive can increase the risk of nozzle clogging in your KMT IDE Diamond cutting head, disrupting the cutting process and potentially damaging equipment.

or contaminants present in recycled garnet abrasive can increase the risk of nozzle clogging in your KMT IDE Diamond cutting head, disrupting the cutting process and potentially damaging equipment.

Increased Wear and Tear: The use of recycled garnet abrasive may result in increased wear and tear on critical components of the waterjet system, such as nozzles, focusing tubes, and mixing chambers, leading to premature failure and costly repairs.

Abrasive Contamination: Recycled garnet abrasive may contain contaminants or foreign particles picked up during previous cutting operations, posing a risk of abrasive contamination that can affect cutting quality and equipment performance.

Inconsistent Cutting Results: Variability in the quality and properties of recycled garnet abrasive can lead to inconsistent cutting results, including uneven cuts, surface defects, and material wastage.

Equipment Damage: Abrasive impurities or irregularities in recycled garnet abrasive may cause abrasion or damage to delicate components of the waterjet system, such as seals, bearings, and high-pressure lines, resulting in costly repairs or replacements.

Safety Hazards: Abrasive contamination or equipment malfunctions resulting from the use of recycled garnet abrasive can pose safety hazards to operators and personnel working in close proximity to the waterjet system.

Decreased System Reliability: The use of recycled garnet abrasive may compromise the overall reliability and uptime of the waterjet system, leading to increased downtime for maintenance and troubleshooting.

Quality Control Challenges: Maintaining consistent quality control over recycled garnet abrasive, including particle size distribution, cleanliness, and hardness, can be challenging, affecting cutting performance and reliability.

Regulatory Compliance Issues: In some industries or applications, the use of recycled garnet abrasive may raise concerns regarding regulatory compliance with environmental regulations, health and safety standards, and material specifications, potentially leading to legal or financial consequences.

To reduce these risks, it’s essential to carefully evaluate the quality and suitability of recycled garnet abrasive, implement robust quality control measures, conduct regular maintenance and inspections of the waterjet system, and adhere to recommended operating procedures and safety protocols. Additionally, consulting with experienced suppliers and industry experts can help minimize risks and ensure the successful integration of recycled garnet abrasive into a waterjet system.

Welcome to KMT Waterjet. To continue, please select a language from the options below.

HELP CENTER

Contact form

KMT Waterjet has global offices to assist you in your region. Contact us using the following form, and the message will be forwarded to the local office which can provide the best support.

Contact form

KMT Waterjet has global offices to assist you in your region. Contact us using the following form, and the message will be forwarded to the local office which can provide the best support.