KMT Waterjet-Frequently Asked Questions ABOUT CONVEYORS AND SLITTERS

Waterjet technology is the preferred CUTTING tool in MOST INDUSTRIES. Here are some common FAQ's about waterjet CONVEYORS AND SLITTERS, powered by KMT Waterjet.

For conveyor waterjet cutting, these FAQs provide a comprehensive overview of the benefits, functionality, and applications of waterjet cutting with conveyors, highlighting how KMT Waterjet’s advanced technology enhances these systems.

What role do KMT Waterjet global OEM partners play? KMT Waterjet global OEM partners design and manufacture custom waterjet conveyor systems tailored to specific industry needs.

What industries benefit from waterjet conveyor systems? Waterjet conveyor systems are beneficial for the food and paper industries.

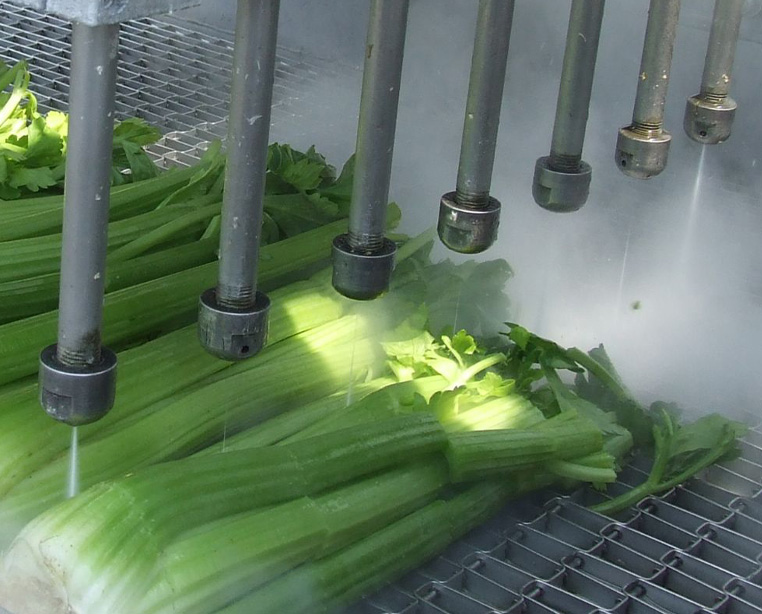

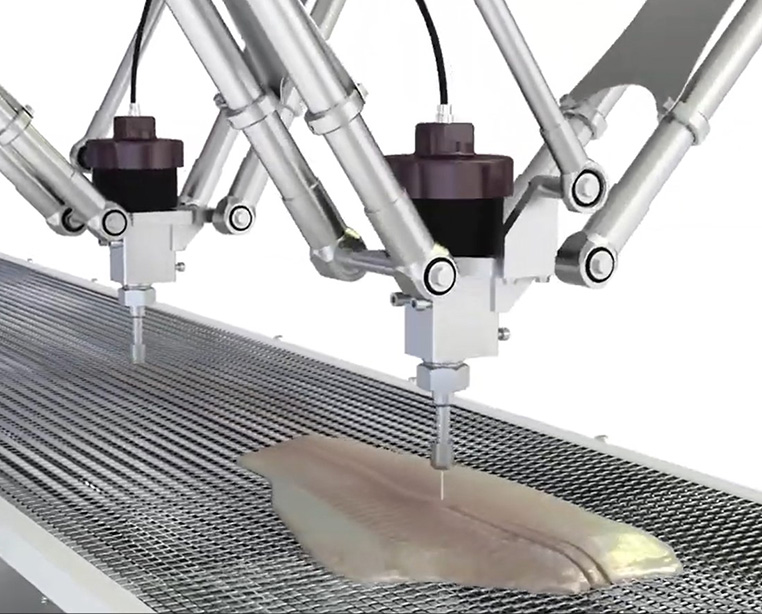

What types of food products can be sliced using waterjet conveyors? Waterjet conveyors can slice various food products including fish, baked goods, protein, and produce.

Waterjet conveyors can slice various food products including fish, baked goods, protein, and produce.

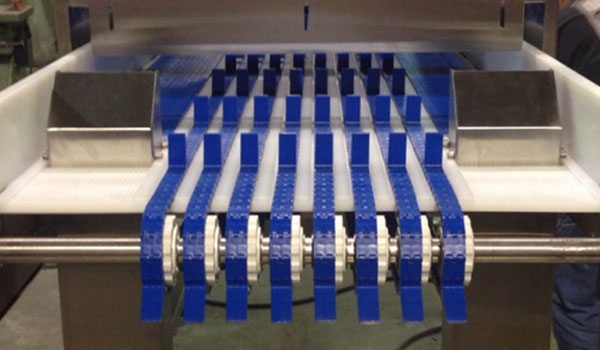

Can waterjet conveyors be used for cutting paper? Yes, waterjet conveyors are also designed to slice paper sheets.

What are the advantages of waterjet cutting over traditional blade methods? Waterjet cutting offers longer shelf life, perfect portion control, eliminates tool replacement, and reduces cross-contamination risks.

How does KMT Waterjet enhance the performance of waterjet cutting systems? KMT Waterjet provides ultrahigh-pressure waterjet pumps and integrates multiple cutting nozzles with OEM custom conveyor machines for enhanced performance and efficiency.

How do KMT Waterjet’s solutions integrate with OEM custom machines? KMT Waterjet collaborates with OEM partners to integrate their ultrahigh-pressure pumps and cutting nozzles seamlessly into custom-designed conveyor systems. KMT has also global Field Service Engineers who can provide 24/7 service and support in over 70 countries around the world, to keep your conveyor systems operating at peak performance with minimal downtime.

KMT Waterjet collaborates with OEM partners to integrate their ultrahigh-pressure pumps and cutting nozzles seamlessly into custom-designed conveyor systems. KMT has also global Field Service Engineers who can provide 24/7 service and support in over 70 countries around the world, to keep your conveyor systems operating at peak performance with minimal downtime.

How does waterjet cutting ensure precision? Precision cutting is ensured through a continuous, clean water flow and a diamond orifice that is .005 inches in diameter.

What types of cutting can be performed with waterjet conveyors? Waterjet conveyors can handle one-dimensional, multiple cutting nozzles, cross-cutting, to 5-axis robotic systems.

Are waterjet conveyor systems automated? Yes, automated waterjet lines facilitate seamless product handling from cutting to packaging and palletizing.

What is the size of the cutting stream in waterjet cutting? The size of the cutting stream is typically the width of a human hair.

What is the speed of the waterjet stream? The waterjet stream can reach speeds up to MACH 3.

Does waterjet cutting cause water absorption in paper products? No, there is no water absorption during the slitting of paper products with water jets.

Does waterjet cutting cause water absorption in paper products? No, there is no water absorption during the slitting of paper products with water jets.

What materials are used for the cutting orifice in waterjet systems? A diamond orifice is used to maximize cutting life and precision.

Can waterjet cutting systems handle multiple types of cuts? Yes, waterjet systems are adaptable for various types of cuts, including one-dimensional and multiple nozzle cuts.

How does waterjet cutting contribute to product shelf life? By avoiding heat and physical contact, waterjet cutting helps maintain the freshness and quality of food products, extending their shelf life.

Is there any risk of cross-contamination with waterjet cutting? Waterjet cutting eliminates cross-contamination risks as it avoids direct contact with the products.

How does waterjet cutting ensure perfect portion control? The precision of the waterjet stream allows for consistent and accurate portion sizes.

How does waterjet cutting ensure perfect portion control? The precision of the waterjet stream allows for consistent and accurate portion sizes.

Are waterjet conveyor systems customizable? Yes, waterjet conveyor systems can be customized with different cutting configurations and automation levels, including KMT’s ultrahigh-pressure waterjet pumps and multiple cutting nozzles.

What kind of automation is available with waterjet cutting systems? Automated waterjet lines can include cutting, packaging, and palletizing functions.

Do waterjet systems require frequent tool replacements? No, waterjet systems eliminate the need for frequent tool replacements, unlike traditional blade methods.

What is the environmental impact of waterjet cutting? Waterjet cutting is environmentally friendly as it uses water as the cutting medium and minimizes waste.

What makes KMT Waterjet’s pumps and nozzles unique? KMT Waterjet’s pumps are designed for ultrahigh-pressure applications, and their cutting nozzles are engineered for precision and durability, ensuring high-quality cuts every time.

What benefits do KMT Waterjet’s ultrahigh-pressure pumps offer? KMT Waterjet’s ultrahigh-pressure pumps deliver powerful, consistent water streams that enhance cutting precision and efficiency.

Can KMT Waterjet’s systems be adapted for different production lines? Yes, KMT Waterjet’s systems are highly adaptable and can be customized to fit various production line requirements, ensuring optimal performance.