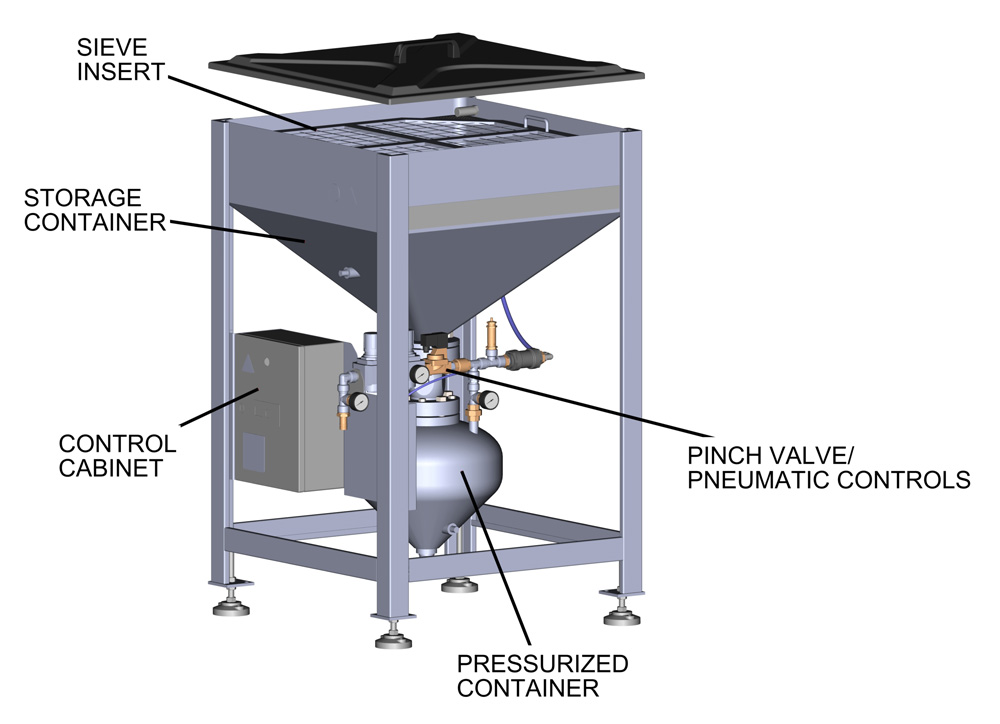

ABRALINE IV ADVANCED Abrasive Hopper storage system

Precisely monitors abrasive feed usage during entire cutting process. Designed for large cutting machines which operate continuously and with multiple cutting heads. Capacity – 1.000 kg

METAL | STONE | GLASS

KMT Waterjet ABRALINE IV COMFORT Series Abrasive Hopper - Continuous Level Monitoring for an Efficient Production Process

Production reliability requires constant monitoring of the entire cutting process. An economical and successful cutting process depends greatly on a constant abrasive flow rate. This fact becomes even more important when cutting brittle materials such as stone, marble or glass.

- Abrasive Flow Monitoring Saves Time and Costs

Our ABRALINE feeding system precisely monitors the availability of sufficient abrasive closely during the

entire cutting process. This protects your valuable material from damage and saves unnecessary costs

and time. Its concept assures process stability, security and a very high degree of reliability. - TWO TANKS FOR A CONTINUOUS ABRASIVE FLOW

The ABRALINE transfer system consists of a big silo for the abrasive and a smaller tank which lies

directly underneath. This vessel contains abrasive sand pressurized by compressed air. The connected

flexible hose guides the abrasive directly to the abrasive metering system of each cutting head.

Additionally, the system features a control cabinet with a control relay which continuously monitors operating

states and relays the corresponding signals to the pneumatic system and the control lights. - SENSORS MONITOR ABRASIVE AVAILABILITY

- Both of the tanks contain level sensors in the sand exit slot areas. Their signals are constantly monitored in the

control station located in the electrical cabinet. When the abrasive level in the vessel reaches its minimum,

the respective sensor gives a signal to the control relay which then opens the valve at the vessel inlet

to automatically refill the vessel with abrasive. If the abrasive level in the upper tank is lower than required,

a warning light begins to flash thus informing the operator to replenish the feeding hopper with abrasive

sand.

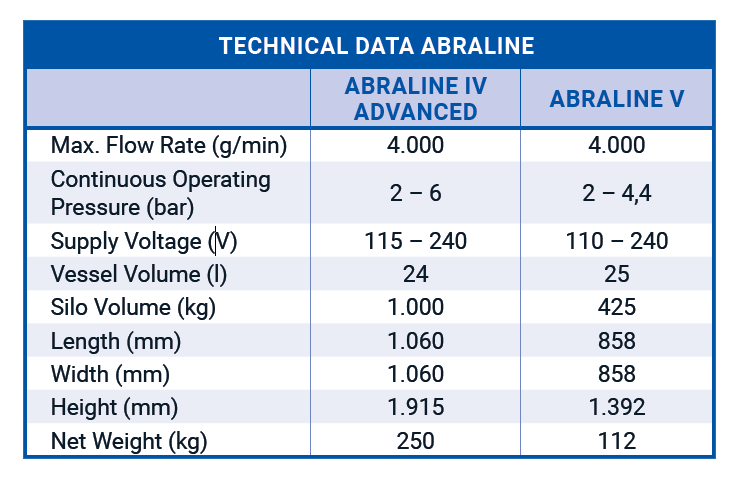

THE CONVENIENT SOLUTION FOR DIFFERENT DEMANDS

KMT offers the ABRALINE feeding system in two different sizes suitable for different requirements. The smaller version ABRALINE V is sufficient for ensuring the abrasive feed for average cutting needs. For large cutting machines which operate continuously and with multiple cutting heads, we recommend the model ABRALINE IV Advanced.