FAQ'S - KMT Waterjet cutting systems in the Manufacturing Industry

KMT Waterjet cutting systems in the Manufacturing Industry

Q-What makes waterjet technology the preferred choice as a cutting solution in the manufacturing industry?

A-Waterjet technology stands out for its ability to provide precise cutting solutions across a wide range of materials without heat-affected zones and virtually no secondary finishing of the product.

Q-How does waterjet cutting minimize material waste?

A-Waterjet cutting with KMT PRO Series pumps minimizes material waste by using up to 6.200 bar pressure (125hp or 60hp).

Waterjet cuts with minimal kerf, (.011 diamond orifice), enabling intricate designs and optimized material usage through part nesting.

Q-What types of materials can waterjet technology cut?

A-Waterjet technology can cut through various materials, including metal, stainless steel, aluminum, tool steel, mild steel, Invar, composites, glass, ceramics, rubber, foam, stone, marble, granite, quartzite, and even heat-sensitive materials like plastics.

Q-How does waterjet cutting compare to other cutting methods in terms of versatility?

A-Waterjet cutting versatility eliminates the need for multiple tools, adapting well to diverse manufacturing requirements.

Q-Why is waterjet cutting preferred for thicker metals like titanium and aluminum?

A-Waterjet tables cut thicker metals with superior precision compared to plasma cutting, ideal for precision-demanding industries.

Unlike plasma and laser, waterjet cutting often produces finished products without the need for time-consuming secondary finishing processes.

Q-What advantages do waterjet systems offer over traditional cutting methods?

A-Waterjet systems offer advantages such as minimal material distortion, reduced secondary operations, and environmentally friendly operation.

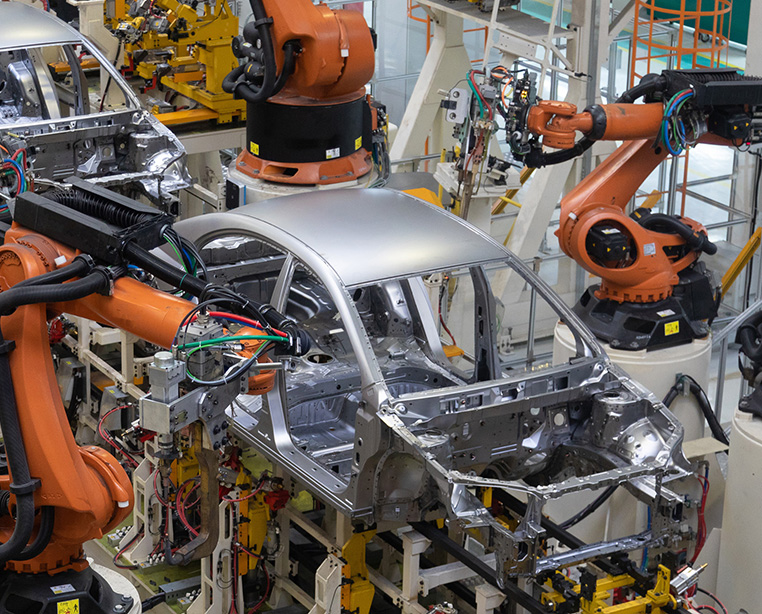

Q-How do advanced features like five-axis cutting and six-axis robotic systems enhance waterjet technology?

Advanced features enable precision and efficiency in cutting complex geometries, benefiting aerospace and metal service industries with abrasive or straight water cutting.

Q-What role do KMT Cutting OEMs play in the adoption of waterjet technology?

KMT Cutting OEMs offer customized CNC cutting tables with software integrated with KMT ultrahigh-pressure pumps (6.200 bar to 3.800 bar ).

Q-How does waterjet cutting contribute to cost-effectiveness in manufacturing?

Waterjet cutting is cost-effective with reduced tooling costs, quick setup, multiple cutting heads for increased capacity, and lower maintenance.

Q-What safety features are inherent in waterjet cutting systems?

Waterjet cutting systems prioritize safety with enclosed chambers, safety interlocks, and remote operation, reducing accident and injury risks.

Waterjet cutting, a cold process, produces no gas emissions, flames, or sparks like plasma and laser cutting methods.

Q-How does waterjet technology address environmental concerns in manufacturing?

A-Waterjet technology uses water and abrasives for cutting, producing minimal waste and eliminating the need for harmful chemicals or emissions, making it environmentally friendly.

Q-Can waterjet cutting systems handle large-scale production demands?

Waterjet systems, especially with KMT Waterjet PRO Series pumps at 6.200 bar, meet large-scale production needs with precision and efficiency.

Waterjet systems can double or triple production runs with multiple cutting nozzles, ideal for high-volume manufacturing.

Q-How does waterjet cutting technology support innovation in product development?

Waterjet cutting fosters innovation in product development by enabling rapid prototyping and exploring new designs in manufacturing.

KMT Waterjet integrates ultrahigh-pressure pump technology with OEM partners to deliver advanced 5-axis and 6-axis robotic cutting systems.

Q-What industries benefit most from waterjet cutting solutions?

A-Industries such as aerospace, automotive, boating, food processing plants, metal fabrication, electronics, and architectural industries benefit significantly from the precision and versatility of waterjet cutting solutions.

Q-What sets waterjet cutting technology apart as the preferred choice for cutting solutions?

A-Waterjet cutting technology’s combination of precision, versatility, cost-effectiveness, and environmental sustainability sets it apart as the preferred choice for cutting solutions in the manufacturing industry. And with the variety of complete waterjet system choices including combination waterjet/saw blade disc, combination waterjet/plasma systems, cross cutting conveyors for the produce industry and even customized cake cutters for slitting pastries, waterjet cutting is the preferred cutting solution by thousands of manufacturing centers.

Q-What makes KMT Waterjet pumps unique, with operating pressures up to 6.200 bar?

A-KMT Waterjet is the pioneer of waterjet pump technology with the first installation of a complete waterjet system in 1971. KMT pumps utilize advanced intensifier technology to achieve pressures up to 6.200 bar, including the World’s Fastest Waterjet, providing exceptional cutting power and precision unmatched by other systems.

Q-How does KMT Waterjet support customers worldwide with field service engineers?

A-KMT Waterjet provides field service engineers who offer expert support to customers around the world, ensuring smooth operations and timely maintenance for their waterjet systems.

Q-What preventive maintenance programs does KMT Waterjet offer?

A-KMT Waterjet offers the comprehensive 65-point preventive maintenance program designed to maximize the efficiency and lifespan of waterjet systems, minimizing downtime and optimizing performance.

Q-In how many countries are KMT Waterjet preventive maintenance programs available?

A-KMT Waterjet preventive maintenance programs are available in over 60 countries worldwide, ensuring that customers in 12 languages for easy communications in the most popular native languages, with access to reliable support and services wherever they operate.