OTHER industry MATERIALS

Waterjet cutting systems have been recognized as the most versatile machine tool in the manufacturing and fabrication sector.

KMT Waterjet - Flexibility for most Industries Materials Cutting

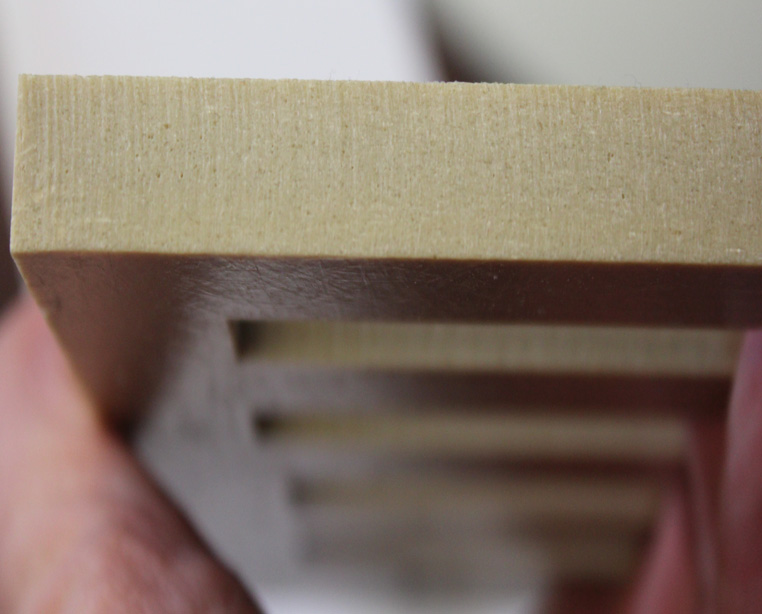

Waterjet cutting is a cold cutting process, with no heat affected zone (HAZ). This gives the flexibility to cut an unlimited variety of materials including cutting metals, stone, food, cutting foam, paper, rubber, carpet, wood, wool, plastics, graphite, tool steel and much more.

KMT Waterjet has a global alliance with over 100 Original Equipment Manufacturers, who specialize in designing standard to custom waterjet machines, slitters and conveyors, integrated with KMT Waterjet, the provider of UHP waterjet pumps, cutting heads and genuine aftermarket parts and technical services. From one cutting head to slitters with multiple cutting nozzles, KMT Waterjet has your answer.

No matter what you are cutting, the KMT OEM network can help you find the best waterjet cutting solution for your company. So, What Are You Cutting? Let us help you

WATERJET CUTTING BENEFITS

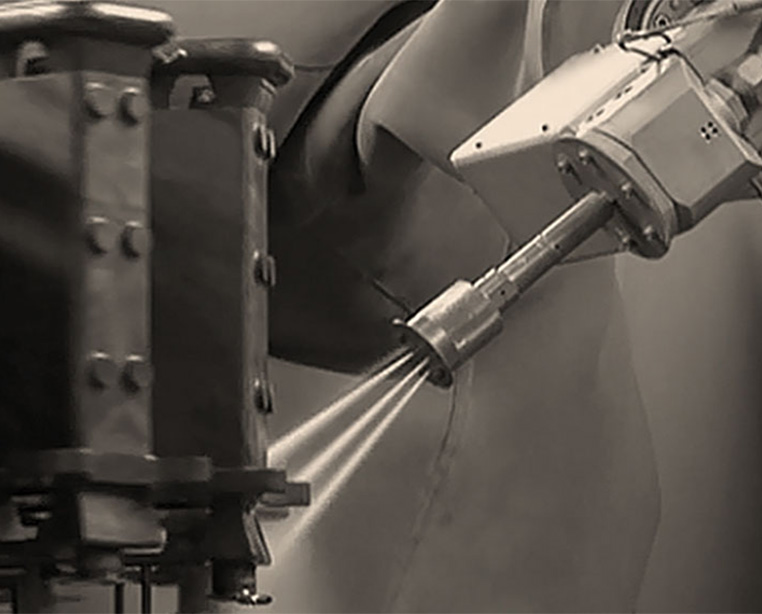

HIGHLY REPEATABLE PERFORMANCE

Waterjet is a proven process for ceramic shell and core removal. Optimal and proven process parameters with robotized waterjet for consistent, quality and performance.

FASTER

Waterjet for stripping materials is up to 10x faster than chemical removal processes, saving time and money. Ultra-high pressure water removes coatings without damaging materials.

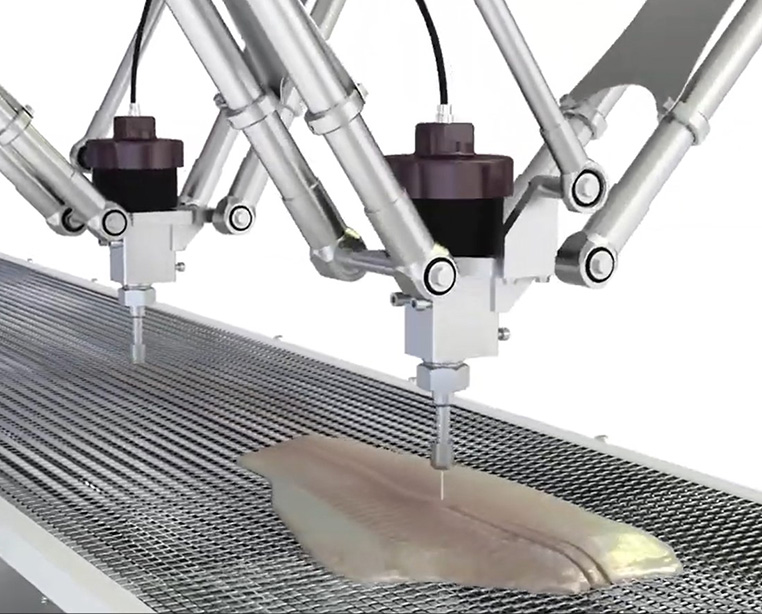

CUSTOMIZED CONVEYOR CUTTING

Automates feeding and cutting process for continuous production.

Tailored to specific cutting needs with multiple cutting nozzles, optimizing performance for cutting food, pin-boning fish, paper, HVAC filters, and more.

WATER-ONLY CROSS CUTTING SOLUTIONS

Specialized in cutting soft materials like rubber, and food products while maintaining product integrity and hygiene.

High-capacity facilities, handle large volumes efficiently, meeting production demands.

COMPLETE WATERJET CUTTING SYSTEMS

Industrial Robotics GoPro Test

Robotic CNC Router with Head-Mounted Camera

Increasing water pressure from 60,000psi to 90,000psi allows you to cut more parts while lowering your abrasive costs. Watch our cutting speed test on a 2 inch thick piece of aluminum to see the difference for yourself.