Waterjet shines in versatility and cold-cutting power, making it a go-to for industries like aerospace, automotive, architecture and fabrication for cutting titanium, foils, rubber, composites, glass and stone.

Waterjet cutting uses high-pressure water (often mixed with abrasives) to slice through materials with precision and versatility.

Below is a KMT comparison chart highlighting the key benefits of waterjet over other common cutting methods focusing on practical advantages like material compatibility, edge quality, speed, and environmental factors.

Note: Benefits can vary by specific application, material, and machine setup provided by our expert OEM’s.

KMT has a global OEM network offering a complete line of waterjet table machines including five-axis waterjet to robotic integrated six-axis motion control.

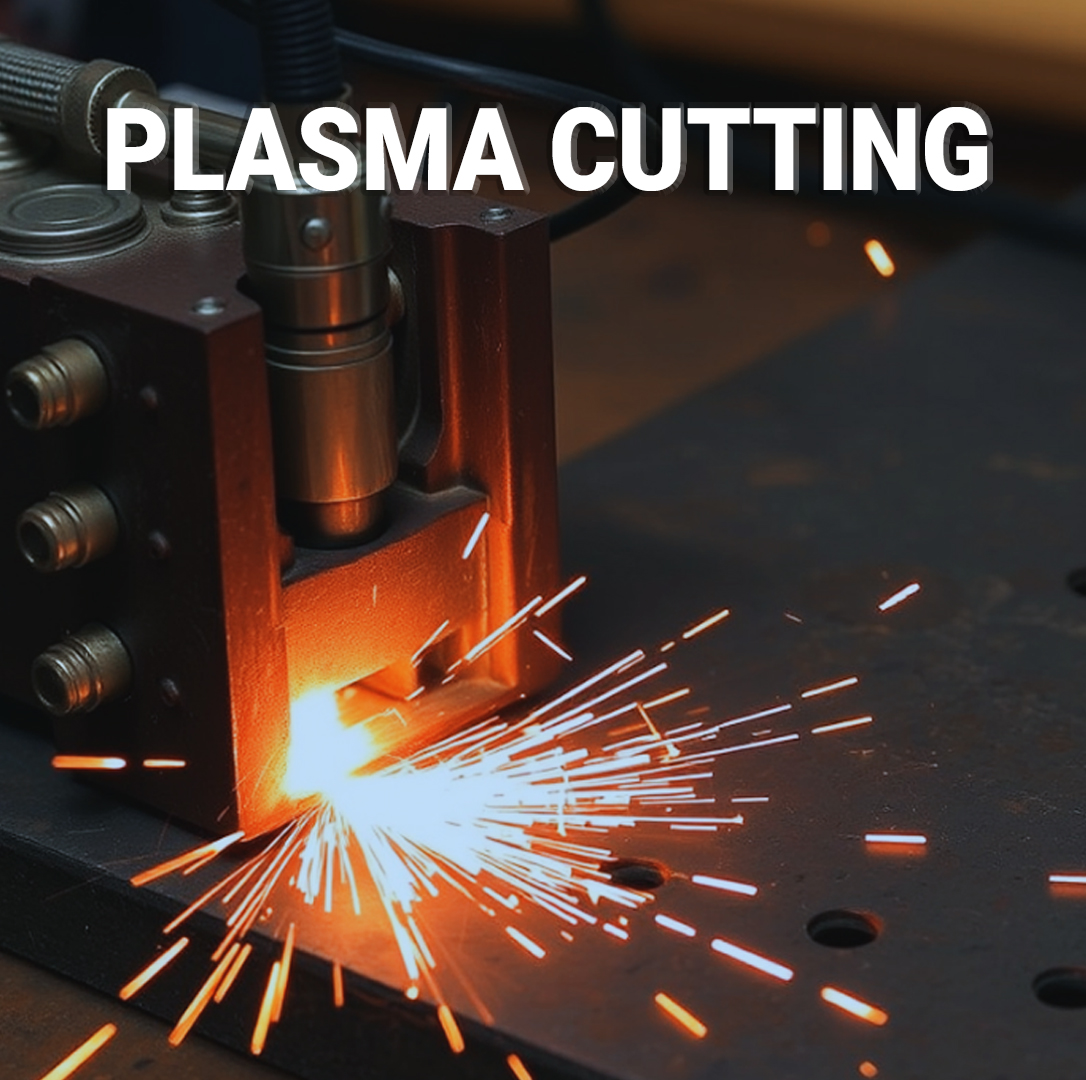

CUTTING METHOD

KEY BENEFITS OF WATERJET

WATERJET WINS! No heat-affected zone (HAZ) means no material warping or hardening; cuts thicker materials and non-metals (like stone or composites) that lasers struggle with; safer for heat-sensitive items without toxic fumes.

WATERJET WINS! Cleaner, smoother edges with less slag and no thermal distortion; handles non-conductive materials (e.g., plastics, ceramics) that plasma can’t; quieter operation and better for intricate designs without rough finishes.

WATERJET WINS! Faster for bulk cutting and works on non-conductive materials; no need for electrodes or dielectric fluids, reducing setup time and costs; versatile for thicker parts without the slow, spark-based erosion process.

WATERJET WINS! No chipping, melting, or dust clouds—ideal for soft woods/plastics without tool wear; precise cuts on irregular shapes and thicker stacks; eco-friendlier with water recycling and no need for expensive bits.

WATERJET WINS! Superior for hard or thick materials that knives can’t penetrate (e.g., metals, glass); higher precision and speed without blade dulling or material compression; enables complex 3D cuts beyond simple straight lines.

WATERJET WINS! Offers greater precision and intricate cutting capabilities than a Saw, especially for detailed shapes and softer materials that might chip or fray with a saw blade; reduces material waste and provides a smoother finish without additional processing.