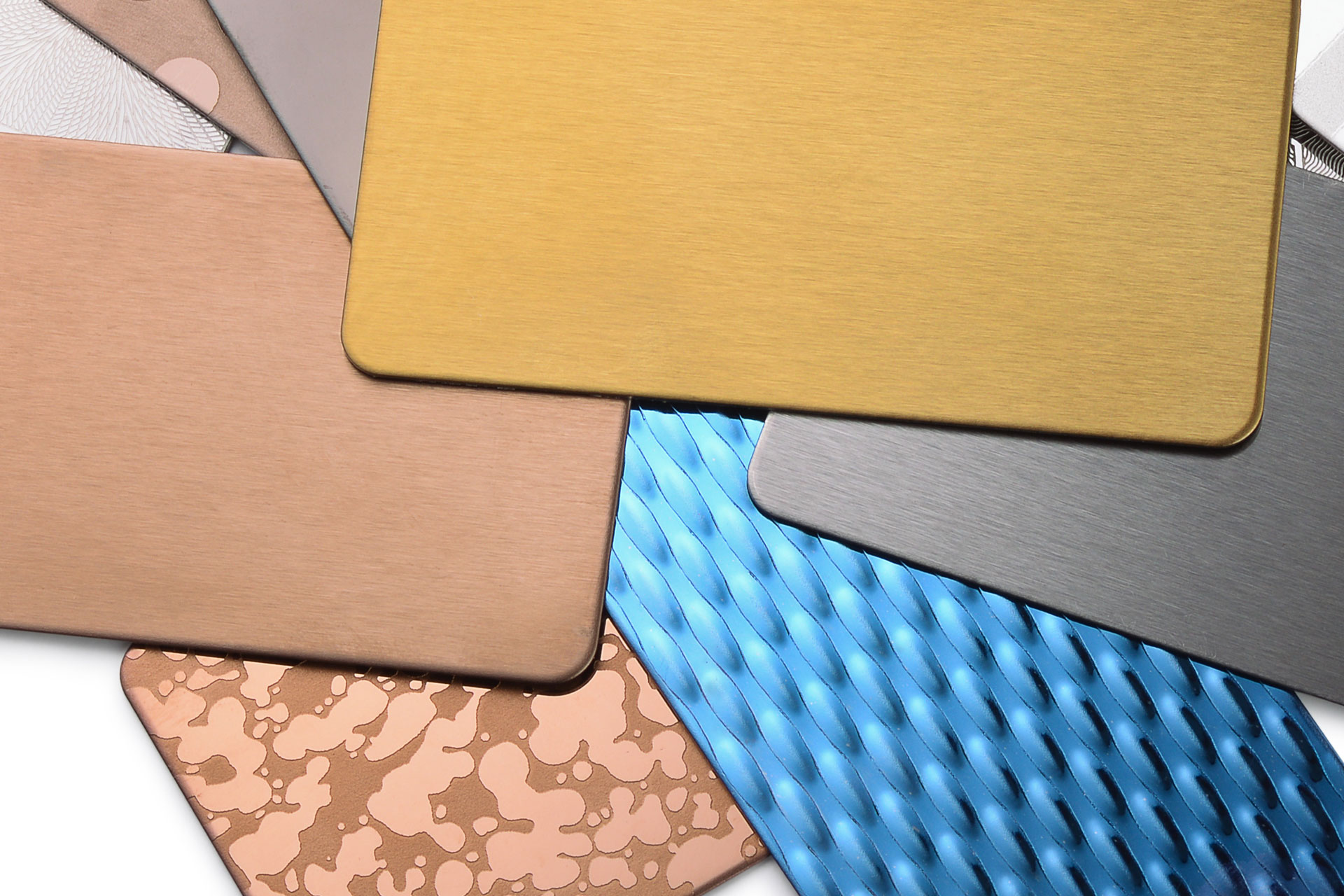

Metal Cutting

KMT waterjet cutting systems can cut titanium steel up to 12" thick, do not require secondary finishing, and leave no heat-affected zone (HAZ).

Learn More

Stone Cutting

Waterjet machines using the KMT Waterjet pumps are perfect for creating corporate logos in decorative designs on walls or inlaid into floors, countertop parts, faucet and sinkholes as well as a smoother radius off sharp edges of slabs cut with saws.

Learn More

Food Cutting

According to Food Production Daily Magazine, “waterjet technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.” The use of pure water in waterjet cutting systems capable of cutting at incredible speeds up to Mach 3, has received USDA approval for creating a bacteria free hygienic cutting process method.

Learn More

Composites Cutting

Because composites are not homogenous materials and are reinforced for greater strength, cutting composites requires a different approach than ceramic cutting or metal cutting, for example. Using conventional cutters and machining techniques will quickly cause parts to wear out and require replacement.

Learn More

HVAC/Insulation Cutting

KMT Waterjet cutting will help to eliminate the duct liner bottleneck in your shop while reducing the labor associated with this process. Using conventional cutters and machining techniques will quickly cause parts to wear out and require replacement.

Learn More

Glass Cutting

Abrasive waterjet cutting technology is a great method for cutting glass because it allows for contours and shapes that cannot be achieved with other cutting machines at a reasonable cost.

Learn More

Cardboard/Paper Cutting

Water jet cutting technology has been used for several decades to perform paper cutting. In fact, this process supersedes the development of the abrasive waterjet used to cut harder materials such as stone, glass, and metals. Unlike abrasive waterjet cutting, however, only pure waterjet is used to cut paper and foods.

Learn More

Plastic Cutting

Water jet cutting technology has been used for several decades to perform plastic and acrylic cutting. In fact, this process supersedes the development of the abrasive waterjet used to cut harder materials such as stone, glass, and metals. Unlike abrasive waterjet cutting, however, only pure waterjet is used to cut plastics and acrylics.

Learn More

Fiberglass Cutting

Waterjet cutting and trimming of fiberglass panels does not delay cutting processes as there is no tool change. With blades, since fiberglass is hard, blades become dull, replacement takes time, and reduces productivity.

Learn More

Other Cutting

Waterjet cutting is a cold cutting process, with no heat affected zone (HAZ). This gives the flexibility to cut an unlimited variety of materials including cutting metals, stone, food, cutting foam, paper, rubber, carpet, wood, wool, plastics, graphite, tool steel and much more.

Learn More